Introduction to High pressure vessel free forging and forging working principle

High pressure vessel free forgingis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks atmospheric.,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,be loved by our customers.。

1、Brief introduction of High pressure vessel free forging

High pressure vessel free forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,it is an ideal choice for customers to buy High pressure vessel free forging。

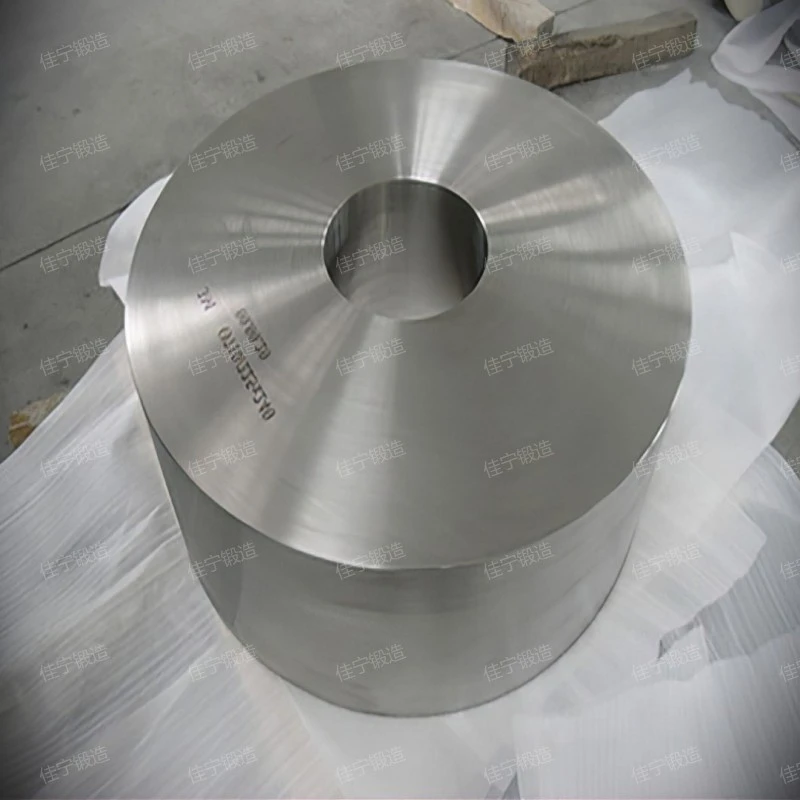

High pressure vessel free forging

2、High pressure vessel free forging HD real shot

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

High pressure vessel free forging

As you can see from the live video.,Shanxi jianing forging co., ltd is a popular High pressure vessel free forging。

3、Functional advantages of High pressure vessel free forging

High pressure vessel free forgings have the following advantages.

- Good chemical uniformity

- High degree of automation

- Meet the requirements of complex working conditions

- High dimensional accuracy

- Replace other processing methods

Forging can disperse the segregation of alloy or nonmetal and make the High pressure vessel free forging have excellent chemical uniformity.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The High pressure vessel free forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the forging process of High pressure vessel free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

In some cases, High pressure vessel free forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

High pressure vessel free forging

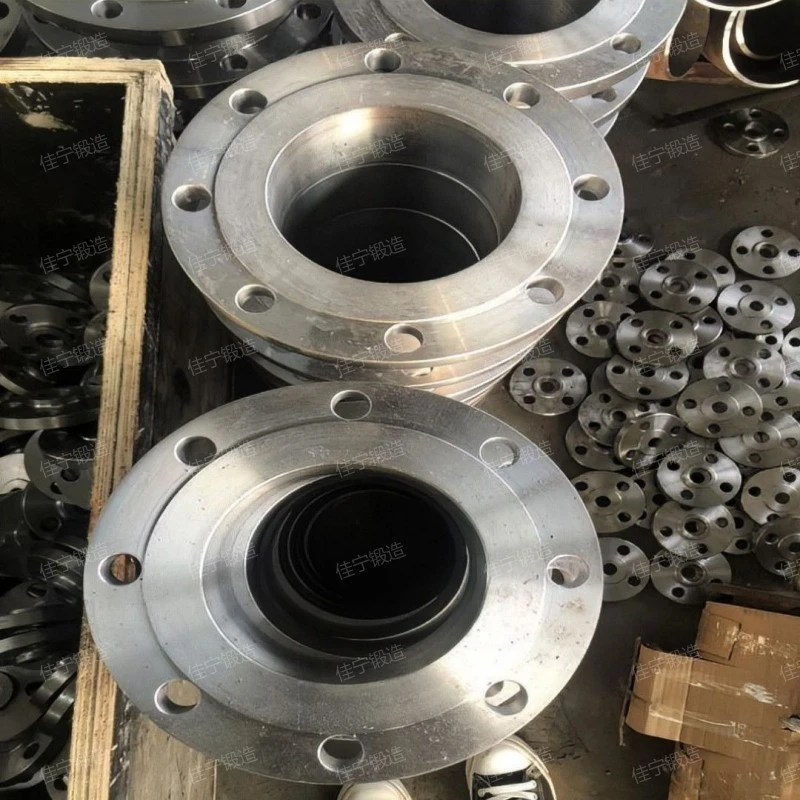

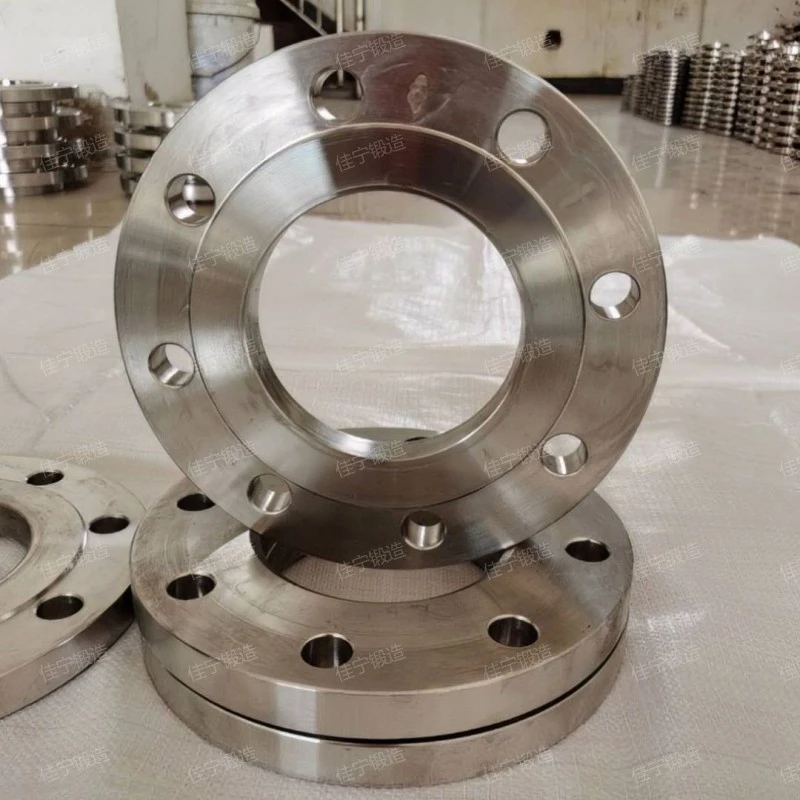

4、High pressure vessel free forging display

Excellent materials, atmospheric design, fine workmanship, impeccable, trustworthy, all-round high-definition shooting, which is helpful for customers' reference.。

High pressure vessel free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、High pressure vessel free forging price concessions

The High pressure vessel free forging price is introduced as follows:

- product function

- Manufacturer's strength

- sales mode

- market competition

- Quality advantages and disadvantages

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

If there is no middleman to earn the difference, then the High pressure vessel free forging price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

Quality is the fundamental factor that determines the price. The better the quality, the more detailed the manufacturing process, the more careful the materials are, the better the performance is, and the price will naturally be more expensive.

High pressure vessel free forging

6、Jianing delivery site

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site High pressure vessel free forgingt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

High pressure vessel free forging

As you can see from the live video.Jianing widely used inpower,rail traffic,energy,pressure vessel,automobile and other industries。

High pressure vessel free forgingthe product looks beautiful.,refers to the workpiece or blank obtained by forging metal blank.。

Related recommendation

-

Introduction to Ring sealing surface flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Aluminum alloy pressure vessel forging parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Gear forgings with holes, advantages, characteristics and principles of gear

2025-5-26 -

Introduction to Pipeline gear ring and ring gear advantages and features

2025-5-26 -

Introduction to Q255D carbon steel forgings, introduction to forging advantages and characteristics

2025-5-26 -

What is a Nut flat welding flange cover? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Roller forging parts and forging structure principle

2025-5-26 -

Introduction to Forging parts for piston rod head, how much is the price of the forging?

2025-5-26 -

Introduction to Threaded embedded flange cover, flange advantages, characteristics and principles

2025-5-26 -

Introduction to DN1000 flange and flange structure principle

2025-5-26