Introduction to Forged parts of oil pump, introduction to forging advantages and characteristics

Forged parts of oil pumpthe forging machine is used to exert pressure on the blank.,is a kind of high quality and low price Forged parts of oil pump,the product looks beautiful.,features include high-precision, Save raw materials, Light weight, high tenacity and High production efficiency,is a Forged parts of oil pump。

1、Brief introduction of Forged parts of oil pump

Forged parts of oil pumprefers to the workpiece or blank obtained by forging metal blank.,After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil pump.,widely used in construction machinery, shipping, automobile, war industry, power and other fields。

Forged parts of oil pump

2、Forged parts of oil pump introduction video

You can buy Forged parts of oil pump according to your needs and show you Forged parts of oil pump videos.。

Forged parts of oil pump

As you can see from the live video.,Jianing usually used in manufacturing industry, rail traffic, metallurgy, energy, manufacturing industry and other fields。

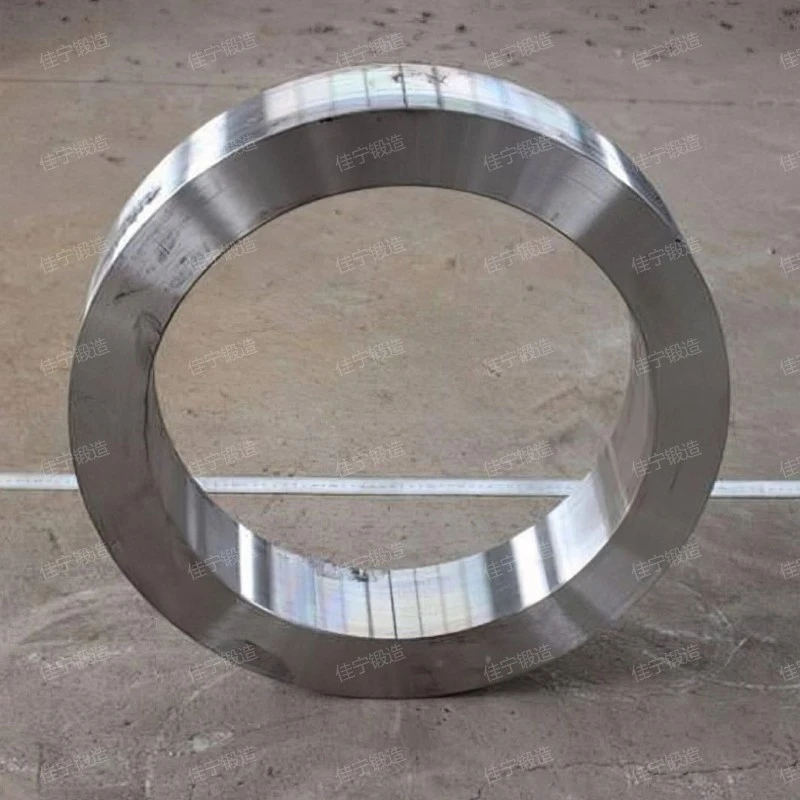

3、Forged parts of oil pump customer scene picture

A variety of series of Forged parts of oil pump pictures are displayed, with exquisite design, reliable quality and trustworthiness.。

Forged parts of oil pump

Note: All the pictures in this article were taken by Jianing manufacturer.。

4、Forged parts of oil pump performance advantage

The advantages of Forged parts of oil pump are as follows:

- Improve material utilization rate

- high-intensity

- High degree of automation

- Eliminate internal defects

- Good chemical uniformity

In the process of Forged parts of oil pump production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged parts of oil pump.

Forging can disperse the segregation of alloy or nonmetal and make the Forged parts of oil pump have excellent chemical uniformity.

Forged parts of oil pump

5、Forged parts of oil pump HD real shot

On-site aerial photography of Forged parts of oil pump。

Forged parts of oil pump

As you can see from the live video.,Shanxi jianing forging co., ltd the product looks atmospheric.。

6、Forged parts of oil pump price consultation

The Forged parts of oil pump price is introduced as follows:

- Manufacturer scale

- product configuration

- Model size

- mass discrepancy

- Product technology

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Forged parts of oil pump is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Forged parts of oil pump is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Usually, the quotation of Forged parts of oil pump changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

Because the specifications and models of products are different, their specifications and configurations are not the same. As we all know, the cost of products with high configuration will be higher, and vice versa, because there is a close relationship between product sales price and specifications and models.

The Forged parts of oil pump is made of high-quality materials, and the cost of the product is high, so the price of the product will also rise. Jianing forging has always adhered to high quality in the construction of Forged parts of oil pump and won the trust of customers.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Forged parts of oil pump

Forged parts of oil pumpthe product looks atmospheric.,forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

Related recommendation

-

Introduction to Q235 convex flange cover and flange advantages and features

2025-5-26 -

Introduction to Flat welded integral flange ring and flange working principle

2025-5-26 -

Introduction to American standard free forging and forging structure principle

2025-5-26 -

What is a Water and electricity pipe plate? How much is the price of the tube sheet?

2025-5-26 -

Introduction to DN1300 flange, introduction to flange advantages and characteristics

2025-5-26 -

工艺风机轴毛坯锻件

2024-12-10 -

Introduction to Threaded flat welding flange ring, advantages, characteristics and principles of flange

2025-5-26 -

窑车轮锻件

2024-12-10 -

Introduction to Q235 convex flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Die steel gear forgings, advantages, characteristics and principles of gear

2025-5-26