What is a Pressure vessel cylinder forgings? Introduction to the advantages and characteristics of the forging

Pressure vessel cylinder forgingsrefers to the workpiece or blank obtained by forging metal blank.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Pressure vessel cylinder forgings.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Pressure vessel cylinder forgings can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。The following is to introduce the Pressure vessel cylinder forgings:

1、Brief introduction of Pressure vessel cylinder forgings

Pressure vessel cylinder forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,it is an ideal choice for customers to buy Pressure vessel cylinder forgings。

Pressure vessel cylinder forgings

2、Introduction of Pressure vessel cylinder forgings characteristics

Pressure vessel cylinder forgingsfeatures include Can bear large impact force or heavy load., High production efficiency, Great forging flexibility, High productivity and high-precision,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Pressure vessel cylinder forgings can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,the product looks beautiful.。

Pressure vessel cylinder forgings

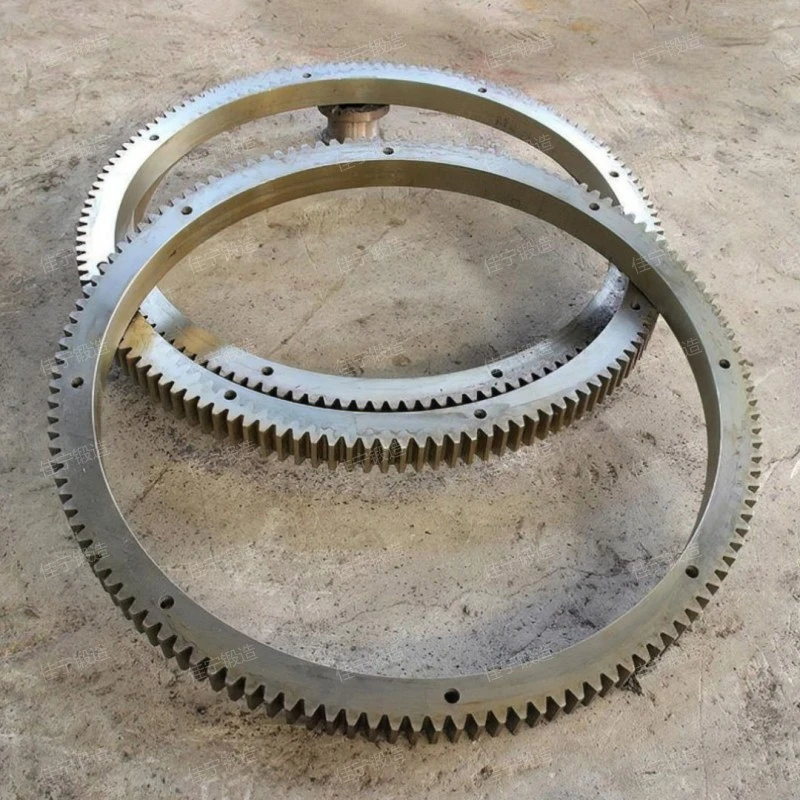

3、Pressure vessel cylinder forgings display

Pressure vessel cylinder forgings HD real shot, showing the product style.。

Pressure vessel cylinder forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Pressure vessel cylinder forgings explanation video

The following is the live video of Pressure vessel cylinder forgings designed and produced by Jianing forging for users, from which we can see the Forging can eliminate metal porosity and holes, and improve the mechanical properties of Pressure vessel cylinder forgings.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties. of JianingPressure vessel cylinder forgings.。

Pressure vessel cylinder forgings

As you can see from the live video.,Jianing forging After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Pressure vessel cylinder forgings.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

5、How much is the Pressure vessel cylinder forgings?

The Pressure vessel cylinder forgings price is introduced as follows:

- raw material

- product function

- brand

- geographical position

- Manufacturer's sales model

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different brands of products in the same series have more or less differences in product prices, and different brands of Pressure vessel cylinder forgings have more or less differences in price.

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

Pressure vessel cylinder forgings

6、Company preferential activities

Pressure vessel cylinder forgings is a new type of forging introduced by Shanxi jianing forging co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for manufacturing industry and other industries. Now consult Jianingproduce的Pressure vessel cylinder forgings, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing

Pressure vessel cylinder forgingsit is widely used in automobile, shipping, power, pressure vessel, metallurgy and other industries,is a Pressure vessel cylinder forgings。

Related recommendation

-

Introduction to Square gear ring forgings, advantages, characteristics and principles of ring gear

2025-5-26 -

What is a Threaded hole plate flange? Introduction to the Working Principle of flange

2025-5-26 -

What is a 12Cr2Ni4 forged parts? How much is the price of the forging?

2025-5-26 -

锥形环锻件

2024-12-10 -

What is a DN125 flange plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Hydraulic cylinder tail forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a Pipe threaded flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to 30CrMo forged parts, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Transmission gear forgings and gear structure principle

2025-5-26 -

碾环机锻件

2024-12-10