Introduction to Forged parts of oil cylinder rod head and forging advantages and features

Forged parts of oil cylinder rod headplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,high tenacity,Light weight,Good mechanical properties,Great forging flexibility,high-precision,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil cylinder rod head.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil cylinder rod head can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,is a kind of high quality and low price Forged parts of oil cylinder rod head,the product looks beautiful.。The following is to introduce the Forged parts of oil cylinder rod head:

1、Brief introduction of Forged parts of oil cylinder rod head

Forged parts of oil cylinder rod headrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is a popular Forged parts of oil cylinder rod head。

Forged parts of oil cylinder rod head

2、Forged parts of oil cylinder rod head explanation video

The following is the live video of Forged parts of oil cylinder rod head designed and produced by Jianing for users, from which we can see the the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties. of Jianing forgingproduce的Forged parts of oil cylinder rod head.。

Forged parts of oil cylinder rod head

As you can see from the live video.,Jianing is a common Forged parts of oil cylinder rod head。

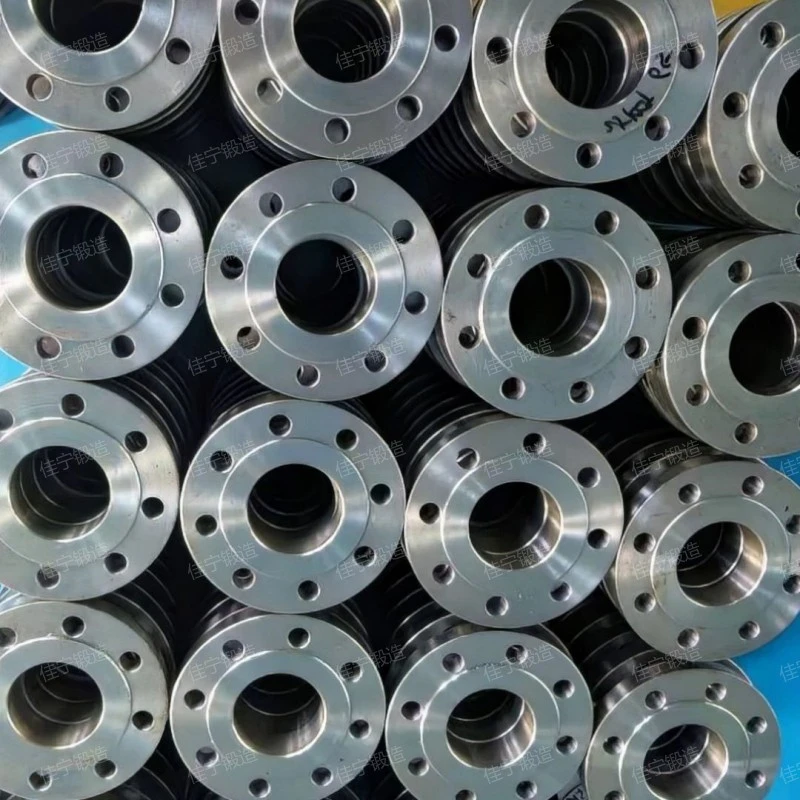

3、Forged parts of oil cylinder rod head real shot picture

The Forged parts of oil cylinder rod head has a beautiful appearance and atmosphere for our customers' reference.。

Forged parts of oil cylinder rod head

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Forged parts of oil cylinder rod head introduction video

Speak directly with facts on the spot。

Forged parts of oil cylinder rod head

As you can see from the live video.,Shanxi jianing forging co., ltd forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

5、How much is the Forged parts of oil cylinder rod head?

The Forged parts of oil cylinder rod head price is introduced as follows:

- Product configuration difference

- service

- Self quality

- model

- Product configuration difference

If the comprehensive configuration of the product is higher, the selling price of the product will be higher, otherwise the price will be lower, so there is a close relationship between the configuration level and the price.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging Forged parts of oil cylinder rod head manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Forged parts of oil cylinder rod head price can meet the purchasing needs of customers.

The quality of the Forged parts of oil cylinder rod head is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the Forged parts of oil cylinder rod head price.

With different specifications, the basic configuration of products will be different, and the price of products with high configuration will naturally be higher, otherwise the price will be lower, so there is a close relationship between specifications and prices.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Forged parts of oil cylinder rod head are closely related. Jianing has comprehensively measured the configuration and sales price of products when designing Forged parts of oil cylinder rod head, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

Forged parts of oil cylinder rod head

6、Jianing after-sales service

Jianing forging adheres to the service concept of "being honest, doing things according to rules, pioneering and innovating, mutual benefit and win-win", and serves every customer wholeheartedly to create quality products and intimate services for customers.。

Jianing

Forged parts of oil cylinder rod headthe product looks atmospheric.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil cylinder rod head can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil cylinder rod head.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,the main features are Great forging flexibility, High production efficiency, high-intensity, Save raw materials and Light weight。

Related recommendation

-

Introduction to Stainless steel forged parts, how much is the price of the forging?

2025-5-26 -

What is a Alloy steel flat welding flange cover? Introduction to the Working Principle of flange

2025-5-26 -

What is a Convex neck flange? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Slotted flange ring, flange advantages, characteristics and principles

2025-5-26 -

Introduction to 2-inch flange plate, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to Protruding face without neck flat welding flange cover and flange structure principle

2025-5-26 -

What is a Conical thread flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Carbon steel pressure vessel forgings and forging structure principle

2025-5-26 -

What is a Flat welding convex steel flange ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to Blind hole sleeve free forging and forging advantages and features

2025-5-26