What is a Forged parts of rotary oil cylinder? Introduction to the advantages, characteristics, and principles of the forging

Forged parts of rotary oil cylinderrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,it can be used in automobile, shipping, energy, pressure vessel, metallurgy and other industries,is a common Forged parts of rotary oil cylinder。

1、Brief introduction of Forged parts of rotary oil cylinder

Forged parts of rotary oil cylinderplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the product looks beautiful.,has been favored by more and more customers.。

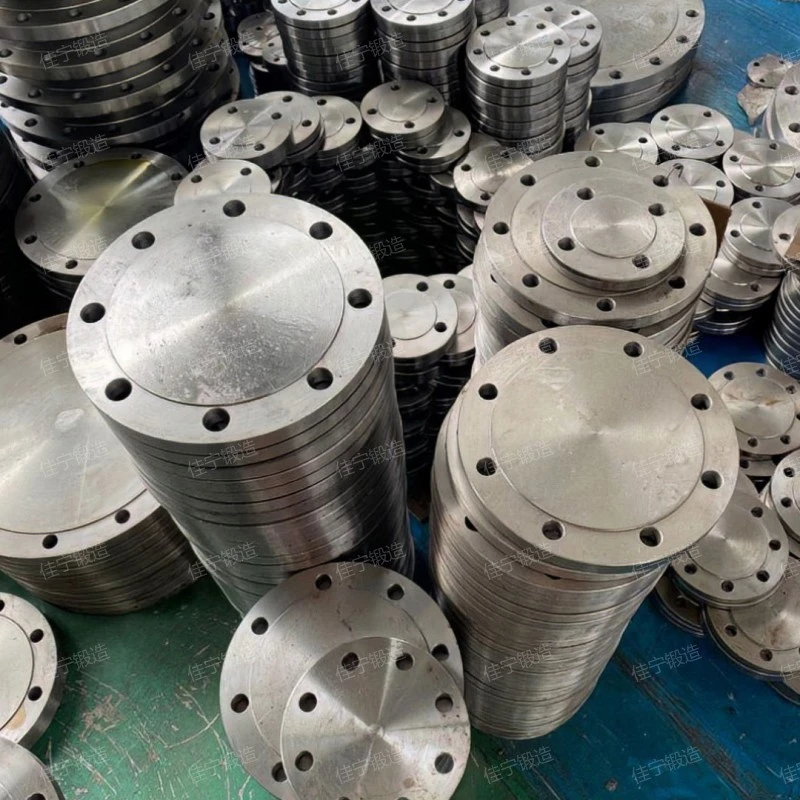

Forged parts of rotary oil cylinder

2、Forged parts of rotary oil cylinder HD picture

The Forged parts of rotary oil cylinder is designed by Jianing forging with advanced technology, and the product has high performance advantages. In order to facilitate our customers to find a satisfactory forging more quickly, the following high-definition pictures are provided for reference.。

Forged parts of rotary oil cylinder

Note: All the pictures in this article were taken by Jianing manufacturer.。

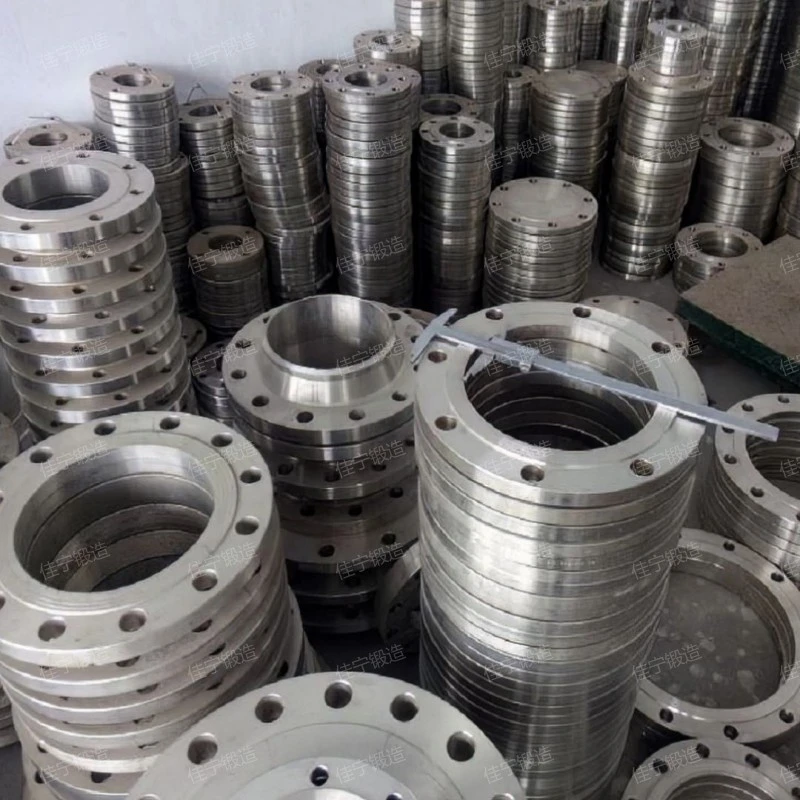

3、Forged parts of rotary oil cylinder HD real shot

High-definition pictures at a glance, beautifully designed atmosphere, stylish, extraordinary temperament, for your visit.。

Forged parts of rotary oil cylinder

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

4、Forged parts of rotary oil cylinder performance advantage

The advantages of Forged parts of rotary oil cylinder are as follows:

- Improve material utilization rate

- Eliminate internal defects

- Meet the requirements of complex working conditions

- Perfect quality assurance system

- Reduce the amount of subsequent processing

In the process of Forged parts of rotary oil cylinder production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Forged parts of rotary oil cylinder.

The Forged parts of rotary oil cylinder has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the process of Forged parts of rotary oil cylinder production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Forged parts of rotary oil cylinder.

The forming precision of the Forged parts of rotary oil cylinder is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Forged parts of rotary oil cylinder

5、Forged parts of rotary oil cylinder price

The Forged parts of rotary oil cylinder price is introduced as follows:

- select a qualified person

- deploy

- raw material

- Company size

- type of operation

The quality of material selection is one of the main factors that directly affect the Forged parts of rotary oil cylinder. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

There is a direct connection between configuration and specifications. Generally speaking, with different specifications, its configuration scheme will be different, and the selection of products' materials and parts will be different, so the sales price of products will be different. It is not difficult to see that the configuration and price of Forged parts of rotary oil cylinder are closely related. Jianing forging has comprehensively measured the configuration and sales price of products when designing Forged parts of rotary oil cylinder, which not only ensures that the functions of products can meet the actual needs of customers, but also can be in terms of price.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Jianing is a self-produced and self-sold Forged parts of rotary oil cylinder, and has rich experience in the production and manufacturing of Forged parts of rotary oil cylinder. In the process of production and manufacturing, there is less waste of resources, and the corresponding product prices are also low.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Forged parts of rotary oil cylinder is low.

Forged parts of rotary oil cylinder

6、Brief introduction of Jianing

Jianing forging, as one of the professional and powerful Forged parts of rotary oil cylinder manufacturers in Shanxi Xinzhou, produces Forged parts of rotary oil cylinder with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

Jianing

Forged parts of rotary oil cylinderForging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of rotary oil cylinder.,Good anti-fatigue performance,Light weight,Good mechanical properties,Good mechanical properties,Light weight。

Related recommendation

-

What is a 35Mn free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to F55 flat welding flange, advantages, characteristics and principles of flange

2025-5-26 -

Introduction to DN2600 flange cover, flange advantages, characteristics and principles

2025-5-26 -

六辊轧机中间轴毛坯锻件

2024-12-10 -

What is a Flat neck butt welded flange cover? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Flat welded steel flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Welding thread flange cover, flange specifications, model parameters

2025-5-26 -

What is a Integral threaded connection flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Pipe sleeve flange, advantages, characteristics and principles of flange

2025-5-26 -

对轧辊毛坯锻件

2024-12-10