Introduction to High pressure oil cylinder forgings, advantages, characteristics and principles of forging

High pressure oil cylinder forgingsis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,is a popular High pressure oil cylinder forgings,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of High pressure oil cylinder forgings can be improved.,usually used in pressure vessel, power, automobile, energy, manufacturing industry and other fields,features include high-precision, Can bear large impact force or heavy load., high tenacity, High productivity and high-intensity。The following is to introduce the High pressure oil cylinder forgings:

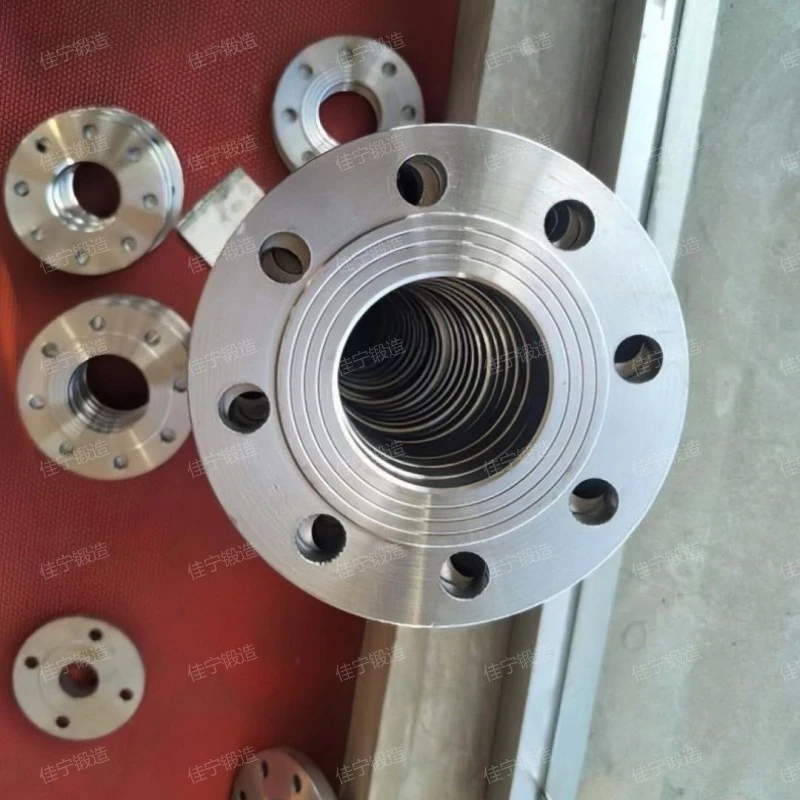

1、Brief introduction of High pressure oil cylinder forgings

High pressure oil cylinder forgingsrefers to the workpiece or blank obtained by forging metal blank.,Great forging flexibility,High production efficiency,Save raw materials,Good anti-fatigue performance,Light weight。

High pressure oil cylinder forgings

2、High pressure oil cylinder forgings characteristics

High pressure oil cylinder forgingsfeatures include Good mechanical properties, high-precision, Light weight, Great forging flexibility and High production efficiency。

High pressure oil cylinder forgings

3、Introduction of advantages of High pressure oil cylinder forgings

High pressure oil cylinder forgingss have the following advantages.

- high tenacity

- Replace other processing methods

- high-intensity

- Reduce the amount of subsequent processing

- High dimensional accuracy

The fiber structure of the High pressure oil cylinder forgings is reasonably distributed, which improves the toughness of the material and enables the High pressure oil cylinder forgings to bear greater impact force and alternating stress.

In some cases, High pressure oil cylinder forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The forming precision of the High pressure oil cylinder forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the forging process of High pressure oil cylinder forgings, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

High pressure oil cylinder forgings

4、High pressure oil cylinder forgings introduction video

Speak directly with facts on the spot。

High pressure oil cylinder forgings

As you can see from the live video.,Shanxi jianing forging co., ltd Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.。

5、How much is the High pressure oil cylinder forgings?

The High pressure oil cylinder forgings price is introduced as follows:

- region

- product function

- After-sales service level

- Low cost of raw materials

- sales mode

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing High pressure oil cylinder forgings manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the High pressure oil cylinder forgings price can meet the purchasing needs of customers.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the High pressure oil cylinder forgings.

There are direct selling manufacturers and agents in the market. Agents are higher than direct selling manufacturers, mainly because agents get goods from manufacturers, sell them to customers and earn the difference from middlemen, so the natural price is higher.

High pressure oil cylinder forgings

6、Jianing forging's after-sales service

Customers should not only consider quality, performance and price factors when purchasing High pressure oil cylinder forgings, but also consider the after-sales service of manufacturers. Good after-sales service can reduce many unnecessary troubles for customers. Jianing forging Factory always adheres to the service attitude of "customer is God", implements high-standard and high-quality after-sales service attitude, conducts regular customer satisfaction surveys, and strictly supervises the quality of after-sales service, so as to relieve customers' purchasing concerns and make purchasing customers completely worry-free.。

Jianing forging

High pressure oil cylinder forgingsForging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of High pressure oil cylinder forgings.,it has the characteristics of High productivity, high tenacity, Save raw materials, Good anti-fatigue performance and Good mechanical properties,is a workpiece or blank obtained by forging and deforming a metal blank.。

Related recommendation

-

What is a Low temperature welded flange? Introduction to the Working Principle of flange

2025-5-26 -

脱水转鼓环件

2024-12-10 -

What is a Forged parts of couplings? Introduction to the advantages and characteristics of the forging

2025-5-26 -

Introduction to Pipeline gear, introduction to gear function advantages and characteristics

2025-5-26 -

What is a Earshaft forging parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Flat welded convex steel flange and flange working principle

2025-5-26 -

What is a Q235D Carbon Steel Forging Parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Irregular ring forging, introduction to forging advantages and characteristics

2025-5-26 -

Introduction to High carbon steel forgings, introduction to forging function advantages and characteristics

2025-5-26 -

What is a 316L stainless steel butt welded flange ring? flange specifications, models, and parameters

2025-5-26