Introduction to Blind hole sleeve forging parts, introduction to forging advantages and characteristics

Blind hole sleeve forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

1、Brief introduction of Blind hole sleeve forging parts

Blind hole sleeve forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Blind hole sleeve forging parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Blind hole sleeve forging parts can be improved.,the product looks atmospheric.,is a common Blind hole sleeve forging parts,is developed and improved by Jianing。

Blind hole sleeve forging parts

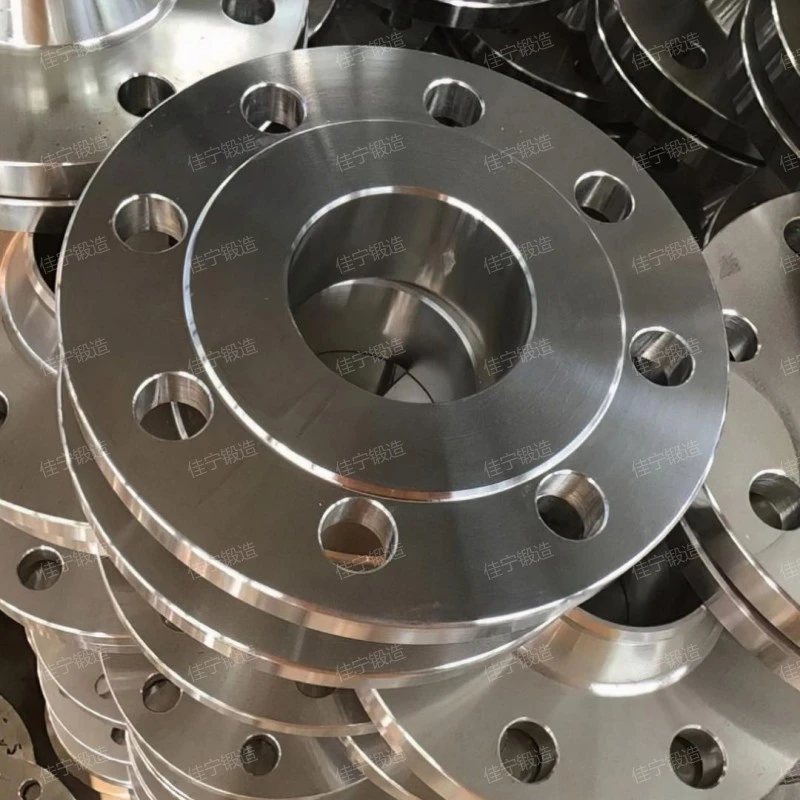

2、Blind hole sleeve forging parts display

Jianing forging Blind hole sleeve forging partsthe product looks beautiful., the following is a panoramic shot of the Blind hole sleeve forging parts for your reference.。

Blind hole sleeve forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Video analysis of Blind hole sleeve forging parts

The following is the live video of Blind hole sleeve forging parts designed and produced by Jianing forging for users, from which we can see the the advantage is After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Blind hole sleeve forging parts.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Blind hole sleeve forging parts can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved. of Jianing forgingBlind hole sleeve forging parts.。

Blind hole sleeve forging parts

As you can see from the live video.,Jianing it has been widely used in construction machinery, power, energy, pressure vessel, metallurgy and other industries。

4、Blind hole sleeve forging parts characteristics

Blind hole sleeve forging partsthe main features are Save raw materials, Good anti-fatigue performance, high-intensity, Light weight and high tenacity。

Blind hole sleeve forging parts

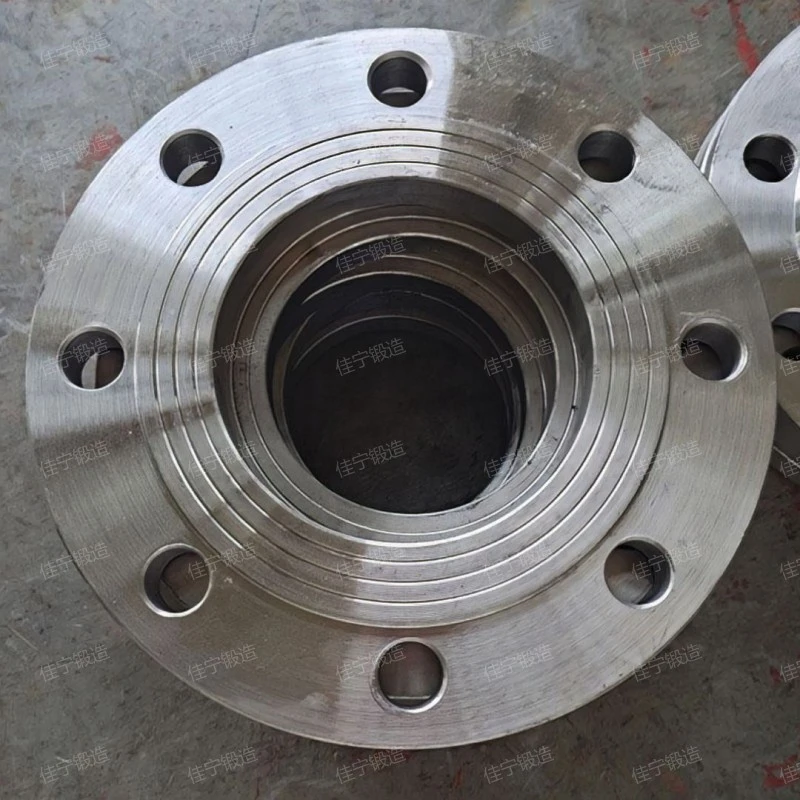

5、Blind hole sleeve forging parts HD real shot

The beauty of Blind hole sleeve forging parts comes from the detail design.。

Blind hole sleeve forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

6、Blind hole sleeve forging parts price advantage

The Blind hole sleeve forging parts price is introduced as follows:

- brand

- Manufacturer's sales model

- cost of production

- Brand strength

- market factors

Different brands of products in the same series have more or less differences in product prices, and different brands of Blind hole sleeve forging parts have more or less differences in price.

If there is no middleman to earn the difference, then the Blind hole sleeve forging parts price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

The production cost determines the price. The production cost here mainly includes technology, materials, technology, manpower and other related factors, among which the technology content is high, and the cost is relatively high, but the performance will be better; The better the quality of raw materials, the greater the cost and the longer the overall life of the product; If the manufacturer has a rational manufacturing process and strict production management system, and can make full use of human and material resources, then it can reduce the waste of expenses and production costs to a great extent, and the Blind hole sleeve forging parts just meets this condition, so as to ensure the high-tech content and high quality of products, it can also enjoy low prices.

At present, there are various brands of Blind hole sleeve forging parts in Shanxi. The performance, quality and after-sales of products under different brands are different, and the prices of Blind hole sleeve forging parts are different.

The market has great fluctuation, which is also the key factor that leads to the imbalance and instability of supply and demand, and then leads to great changes in product prices. Only after a comprehensive understanding and investigation of the market can we make a reasonable decision, and then we can formulate a Blind hole sleeve forging parts price sales plan that customers are satisfied with, and the main reason for its price rationality is also reflected here.

Blind hole sleeve forging parts

Blind hole sleeve forging partsForging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Blind hole sleeve forging parts can be improved.,the product looks atmospheric.。

Related recommendation

-

Introduction to Coupling forgings, forging specifications, model parameters

2025-5-26 -

Introduction to Forged parts of mold steel bearings, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Flat welded square hole flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Flat welding convex flange ring with diameter and flange structure principle

2025-5-26 -

碾环锻件

2024-12-10 -

What is a High pressure oil cylinder end cap forging? Introduction to the Working Principle of forging

2025-5-26 -

What is a Convex panel flat welded steel flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

What is a Flat welding flange ring with protruding plate? Introduction to the Working Principle of flange

2025-5-26 -

Introduction to Double phase steel butt welded flange cover, introduction to flange advantages and characteristics

2025-5-26 -

What is a Q235B butt welded flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26