Introduction to Piston cylinder forgings, advantages, characteristics and principles of forging

Piston cylinder forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the product looks beautiful.,usually used in war industry, metallurgy, power, shipping, automobile and other fields,is a Piston cylinder forgings newly developed by Jianing。The following is to introduce the Piston cylinder forgings:

1、Brief introduction of Piston cylinder forgings

Piston cylinder forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.。

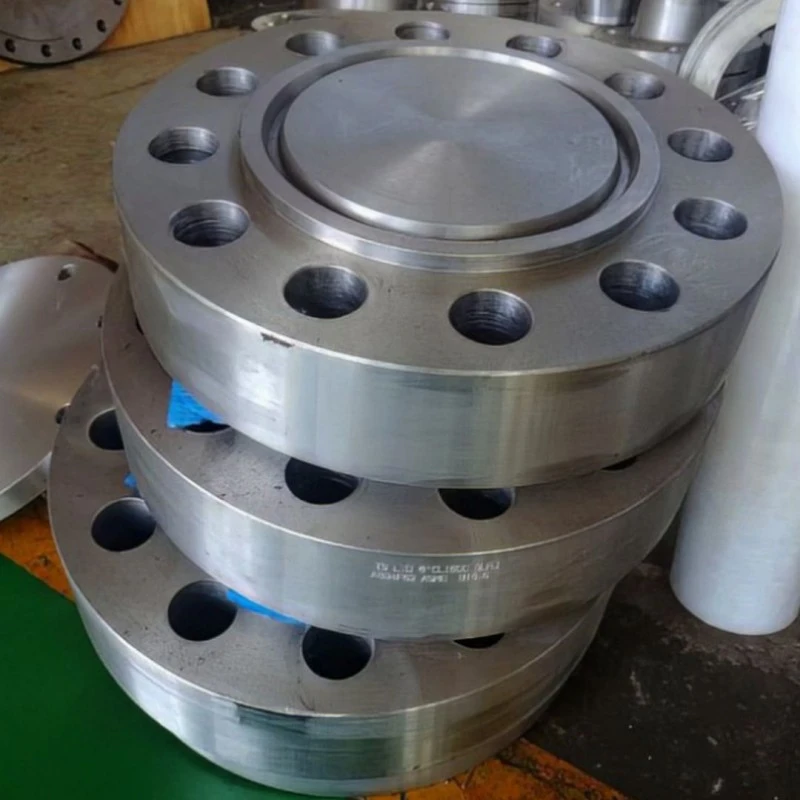

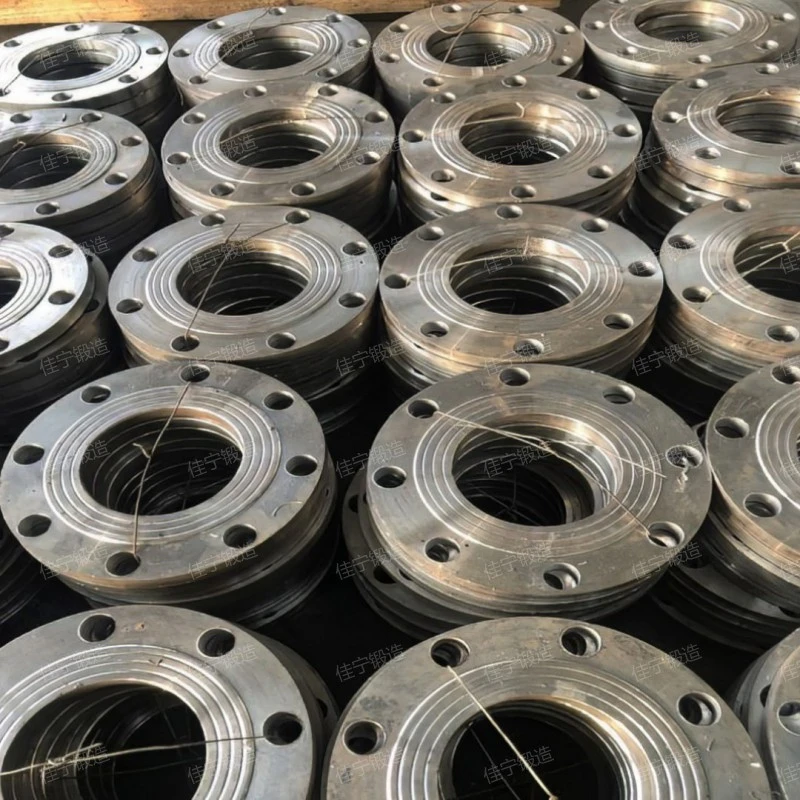

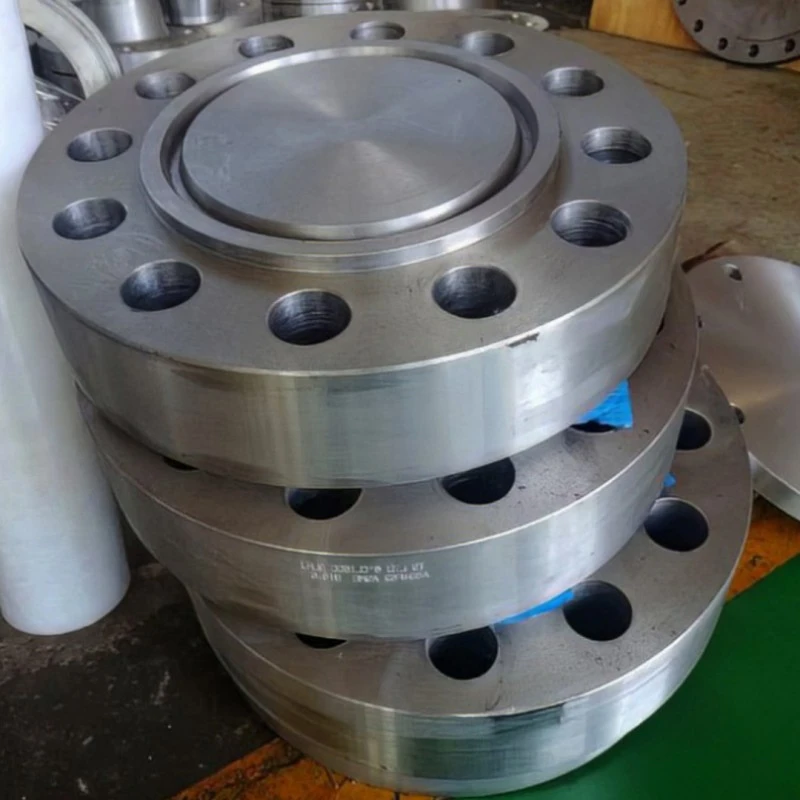

Piston cylinder forgings

2、Introduction of Piston cylinder forgings characteristics

Piston cylinder forgingsit has the characteristics of Good anti-fatigue performance, Great forging flexibility, high-intensity, Light weight and Light weight,the product looks beautiful.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Piston cylinder forgings can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Piston cylinder forgings.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,the forging machine is used to exert pressure on the blank.,be loved by our customers.。

Piston cylinder forgings

3、Functional advantages of Piston cylinder forgings

Piston cylinder forgingss have the following advantages.

- Eliminate internal defects

- Optimizing structural design

- Perfect quality assurance system

- high-intensity

- Replace other processing methods

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Piston cylinder forgings.

On the premise of ensuring the design strength, through reasonable structural design, the Piston cylinder forgings can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

In the process of Piston cylinder forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Piston cylinder forgings.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In some cases, Piston cylinder forgings can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

Piston cylinder forgings

4、Piston cylinder forgings introduction video

Jianing forging provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Piston cylinder forgingst operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Piston cylinder forgings

As you can see from the live video.,Shanxi jianing forging co., ltd it can be used in energy, pressure vessel, rail traffic, manufacturing industry, shipping and other industries。

5、Piston cylinder forgings characteristics

Piston cylinder forgingsfeatures include Save raw materials, Can bear large impact force or heavy load., Good anti-fatigue performance, high-precision and high tenacity,the product looks beautiful.,customizable。

Piston cylinder forgings

6、How much is the Piston cylinder forgings?

The Piston cylinder forgings price is introduced as follows:

- Manufacturer's strength

- Low cost of raw materials

- Sales model

- Model type

- Model specification

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

Production costs include raw material costs, labor costs, other costs, etc., which manufacturers need to invest when producing products, but these factors are not certain. They are affected by the market. When one factor in the market changes, the production costs of manufacturers will also change, and the price of Piston cylinder forgings will also fluctuate to some extent.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

Products generally have a variety of specifications and models to meet the multiple needs of manufacturing. The same is true for Piston cylinder forgings, which have different models and different performances. Therefore, these are all factors that affect the price change of Piston cylinder forgings.

Because there are many models of each product, different customers have different requirements for product performance, and the product specifications and models that are inevitably used will be different. Different models of the same product will lead to different prices.

Piston cylinder forgings

Piston cylinder forgingsthe product looks atmospheric.,is a Piston cylinder forgings,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Piston cylinder forgings can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Piston cylinder forgings.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.。

Related recommendation

-

Introduction to 316 butt welded flange ring and flange advantages and features

2025-5-26 -

Introduction to Threaded reducing flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Variable diameter threaded flange ring and flange structure principle

2025-5-26 -

What is a Buckle flange? How much is the price of the flange?

2025-5-26 -

What is a Concave flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to National standard Class I forgings and forging working principle

2025-5-26 -

Introduction to Alloy steel cylinder free forging, forging specifications, model parameters

2025-5-26 -

What is a Low temperature carbon steel flange? Introduction to the advantages and characteristics of the flange

2025-5-26 -

What is a 20CrNi3 free forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Welding flange plates for petrochemical use? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26