Introduction to Sleeve forging and forging advantages and features

Sleeve forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,the product looks atmospheric.,it has the characteristics of Save raw materials, Light weight, Good anti-fatigue performance, Good mechanical properties and high-precision,is a Sleeve forging,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Sleeve forging can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Sleeve forging.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

1、Brief introduction of Sleeve forging

Sleeve forgingplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the product looks beautiful.。

Sleeve forging

2、Functional advantages of Sleeve forging

Sleeve forgings have the following advantages.

- Good chemical uniformity

- Eliminate internal defects

- High degree of automation

- Reduce the amount of subsequent processing

- Perfect quality assurance system

Forging can disperse the segregation of alloy or nonmetal and make the Sleeve forging have excellent chemical uniformity.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Sleeve forging.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

The forming precision of the Sleeve forging is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

In the process of Sleeve forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Sleeve forging.

Sleeve forging

3、Introduction of Sleeve forging characteristics

Sleeve forgingHigh production efficiency,high tenacity,high-intensity,High productivity,Can bear large impact force or heavy load.,can be customized according to user's needs.。

Sleeve forging

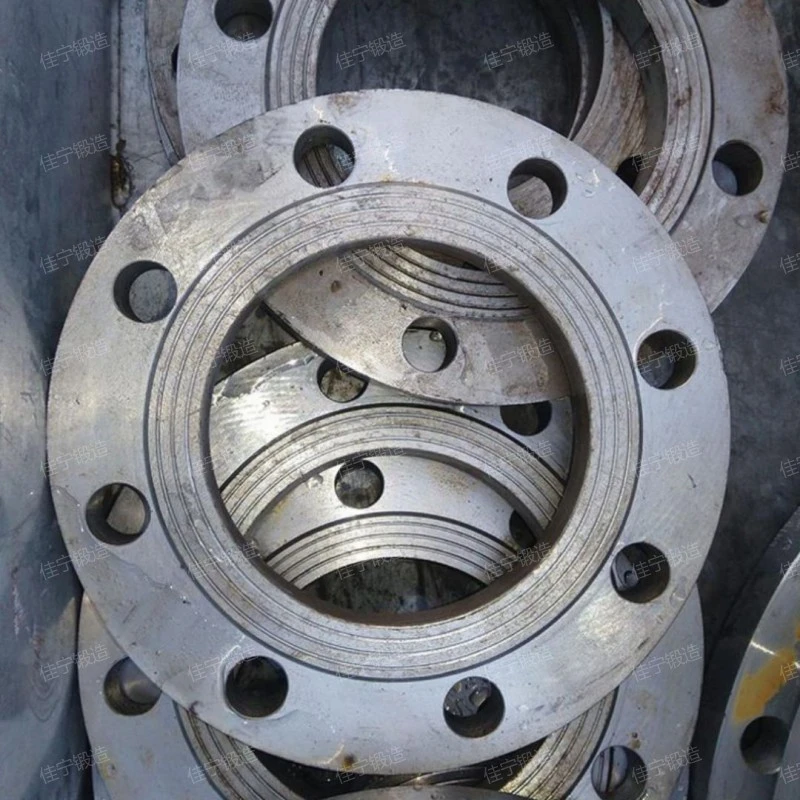

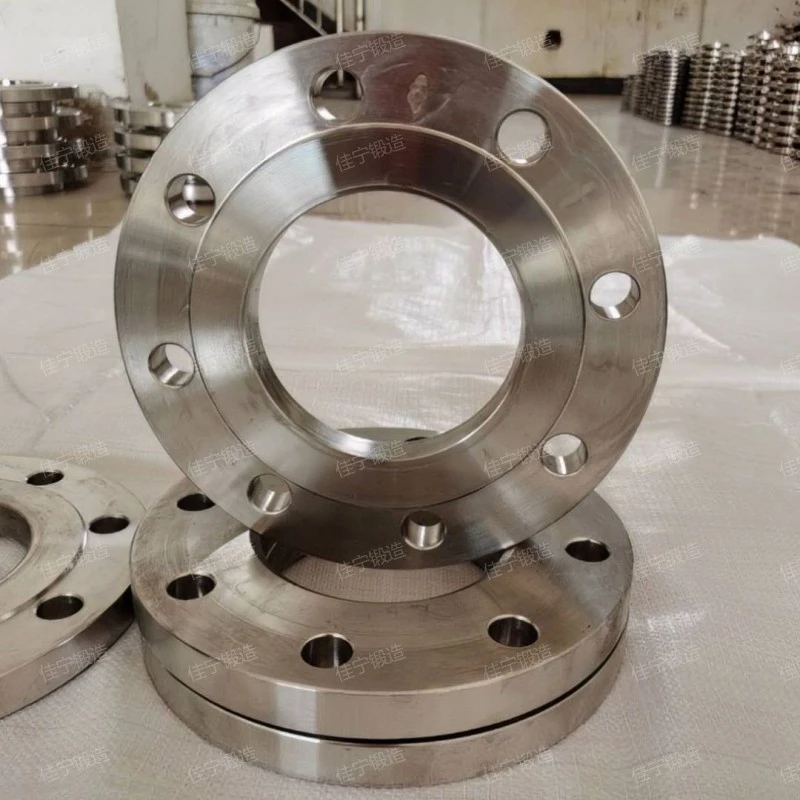

4、Sleeve forging display

Various combinations of Sleeve forging can meet the diverse needs of customers. The following are High definition real shot andthe product looks atmospheric., which are trustworthy.。

Sleeve forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Sleeve forging price advantage

The Sleeve forging price is introduced as follows:

- select a qualified person

- product function

- technology content

- product quality

- market

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Sleeve forging will vary greatly. Jianing attaches great importance to the quality of products, and the formulation of prices is also reasonable.

With the increasingly fierce competition of Sleeve forging, market factors have a certain influence on the price of Sleeve forging. When the demand in the market increases and the supply remains unchanged, the price will rise. On the contrary, the price will fall. When there is an increase in supply and the demand remains unchanged, the price will rise, on the contrary, the price will fall.

Sleeve forging

6、Company preferential activities

Sleeve forging is a new type of forging introduced by Jianing forging manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for metallurgy and other industries. Now consult Sleeve forging, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

Jianing forging

Sleeve forgingfeatures include Save raw materials, Great forging flexibility, Light weight, high-intensity and Save raw materials,the product looks beautiful.。

Related recommendation

-

What is a Plate welded steel flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Q345R ring gear, ring gear advantages, characteristics and principles

2025-5-26 -

What is a Type II pressure vessel forgings? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

Introduction to DN3400 flange and flange working principle

2025-5-26 -

What is a Convex threaded flange? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Threaded welded flange ring, flange specifications, model parameters

2025-5-26 -

Introduction to Composite steel pipe welded flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

Introduction to Square flat welding flange cover, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Variable diameter convex flange ring and flange advantages and features

2025-5-26 -

What is a Threaded protruding flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26