Introduction to Outer cylinder forging parts, how much is the price of the forging?

Outer cylinder forging partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the product looks atmospheric.,features include High productivity, High production efficiency, high-precision, Great forging flexibility and Light weight,usually used in automobile, energy, construction machinery, rail traffic, rail traffic and other fields,is developed and improved by Jianing。

1、Brief introduction of Outer cylinder forging parts

Outer cylinder forging partsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the advantage is After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Outer cylinder forging parts can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

Outer cylinder forging parts

2、Outer cylinder forging parts performance advantage

Outer cylinder forging partss have the following advantages.

- Good chemical uniformity

- Meet the requirements of complex working conditions

- Good fatigue resistance.

- Reduce the amount of subsequent processing

- Eliminate internal defects

Forging can disperse the segregation of alloy or nonmetal and make the Outer cylinder forging parts have excellent chemical uniformity.

The Outer cylinder forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The particle flow inside the Outer cylinder forging parts flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

The forming precision of the Outer cylinder forging parts is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Outer cylinder forging parts.

Outer cylinder forging parts

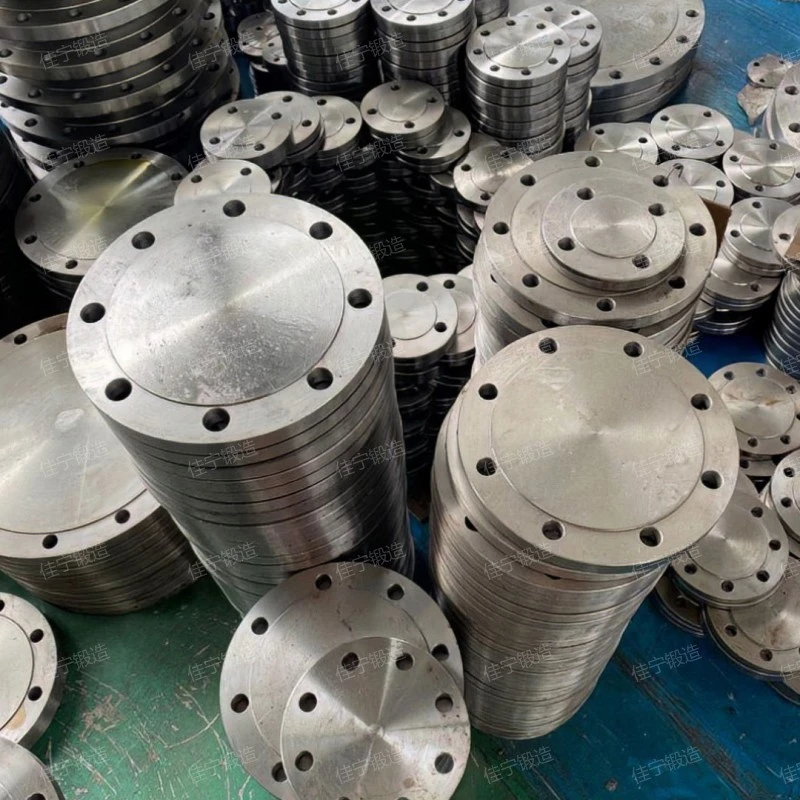

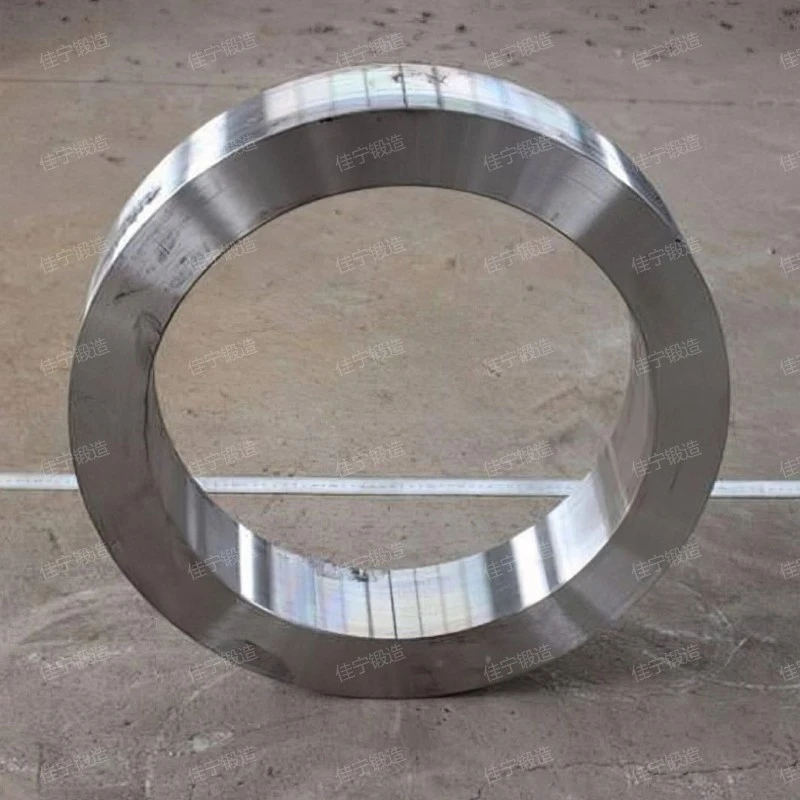

3、Outer cylinder forging parts field real shot

Speak directly with facts on the spot。

Outer cylinder forging parts

As you can see from the live video.,Jianing forging widely used in energy, construction machinery, power, shipping, war industry and other fields。

4、Introduction of Outer cylinder forging parts characteristics

Outer cylinder forging partsfeatures include High production efficiency, Good mechanical properties, Good anti-fatigue performance, high-intensity and High productivity,it can be used in pressure vessel, automobile, metallurgy, manufacturing industry, construction machinery and other industries,is a kind of high quality and low price Outer cylinder forging parts,customizable。

Outer cylinder forging parts

5、Outer cylinder forging parts customer scene picture

Haide Outer cylinder forging parts manufacturing factory。

Outer cylinder forging parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

6、Outer cylinder forging parts quotation

The Outer cylinder forging parts price is introduced as follows:

- market quotation

- mass discrepancy

- cost of production

- deploy

- company strength

Market supply and demand is the main objective factor to determine the price, and the imbalance between supply and demand affects the price change. Generally speaking, when the Outer cylinder forging parts market is in short supply, its price will increase relatively; On the contrary, when the supply exceeds the demand, it also indicates that the competition among manufacturers is fierce. In order to better improve the visibility of manufacturers and occupy a more favorable market position, manufacturers will generally lower their prices appropriately; Only when the market supply and demand reach a balanced state can its normal price be realized.

The quality of the Outer cylinder forging parts is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the Outer cylinder forging parts price.

Cost is a direct and fundamental factor that affects the price of Outer cylinder forging parts. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in Outer cylinder forging parts price, low in cost and low in price.

Configuration refers to the hardware composition of the product, which mainly includes material selection, parts selection, etc. The higher the overall configuration of the product, the higher the price of the Outer cylinder forging parts, which is beyond doubt. Jianing forging makes every product with great care in the attitude of being highly responsible to customers, so the price of Jianing forging Outer cylinder forging parts is reasonable for products with the same configuration.

The nature of the manufacturer can also greatly affect the price of the Outer cylinder forging parts. General manufacturers are divided into direct sellers, agents and middlemen. If they are direct selling manufacturers, there are not too many intermediate links, and their sales prices are low.

Outer cylinder forging parts

Outer cylinder forging partsthe product looks beautiful.,is a Outer cylinder forging parts,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Outer cylinder forging parts.、After forging, its structure and mechanical properties can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.。

Related recommendation

-

Introduction to High strength steel forgings, forging advantages, characteristics and principles

2025-5-26 -

What is a S355JR alloy forgings? Introduction to the advantages and characteristics of the forging

2025-5-26 -

What is a Welded flange cover with holes? flange specifications, models, and parameters

2025-5-26 -

What is a Raised panel flat welding flange ring? How much is the price of the flange?

2025-5-26 -

Introduction to Flat welding flange plate with convex surface and flange structure principle

2025-5-26 -

What is a DN65 flange plate? Introduction to the advantages and characteristics of the flange

2025-5-26 -

Introduction to Rotary cover flat welding flange ring, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Half ring forged parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a Aluminum alloy forged parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to 304 stainless steel forged parts, forging advantages, characteristics and principles

2025-5-26