Introduction to Cone free forging and forging working principle

Cone free forgingrefers to the workpiece or blank obtained by forging metal blank.。The following is to introduce the Cone free forging:

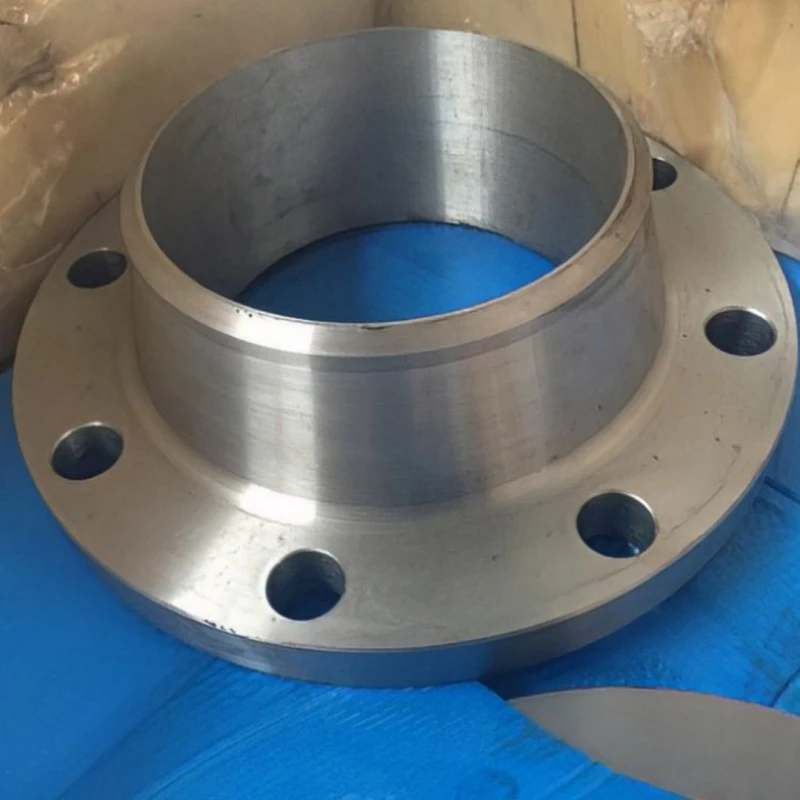

1、Brief introduction of Cone free forging

Cone free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,it is an ideal choice for customers to buy Cone free forging。

Cone free forging

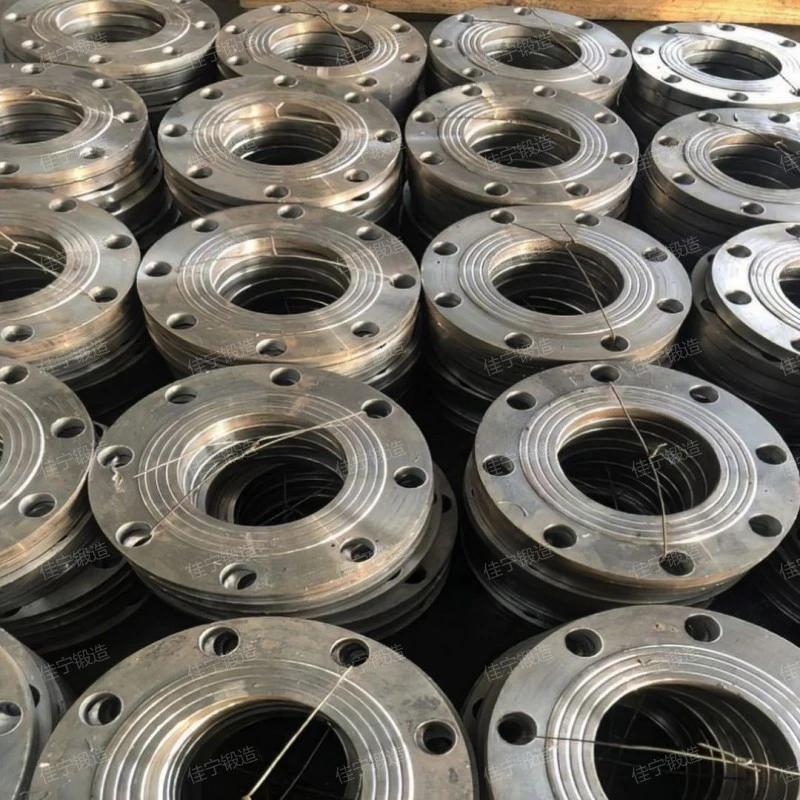

2、Cone free forging work site real shot

A variety of series of Cone free forging pictures are displayed, with exquisite design, reliable quality and trustworthiness.。

Cone free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Cone free forging video

The following is the live video of Cone free forging designed and produced by Jianing for users, from which we can see the the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting. of Jianingproduction-manufacturing的Cone free forging.。

Cone free forging

As you can see from the live video.,Jianing forging the product looks beautiful.。

4、Physical picture of Cone free forging

Cone free forging have various specifications and models, which can meet the diverse needs of users. The following are high-definition real pictures, which are exquisite in workmanship and trustworthy.。

Cone free forging

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、Cone free forging characteristics

Cone free forgingfeatures include Great forging flexibility, Save raw materials, Good anti-fatigue performance, high-intensity and high-precision,it is widely used inmanufacturing industry,war industry,construction machinery,rail traffic,power and other industries,is a common Cone free forging。

Cone free forging

6、Cone free forging price concessions

The Cone free forging price is introduced as follows:

- market supply and demand

- After-sales service level

- Brand strength

- Cost input

- product configuration

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. Jianing has a deep understanding of this factor, so the price of our Cone free forging is more reasonable.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Cone free forging price and service can meet the actual needs of customers.

At present, there are various brands of Cone free forging in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Cone free forging are different.

When the Cone free forging is produced, the materials selected by different manufacturers will be different. Some manufacturers use high-quality materials, and the price will be relatively high, while some manufacturers use ordinary materials, and the price will be lower.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. Jianing pays special attention to the hardware configuration of products, so Jianing forging Cone free forging has a higher cost performance.

Cone free forging

Cone free forgingthe product looks beautiful.,After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Cone free forging can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Cone free forging.,it has the characteristics of High production efficiency, high tenacity, Light weight, High productivity and Good mechanical properties。

Related recommendation

-

What is a Flat welding flange ring with protruding surface? flange specifications, models, and parameters

2025-5-26 -

20SiMn电机轴锻件

2024-12-10 -

What is a Double sided butt welded flange plate? Introduction to the principle of flange structure

2025-5-26 -

Introduction to 10 inch flange and flange structure principle

2025-5-26 -

V80风机主轴毛坯锻件

2024-12-10 -

What is a Rotary cover plate flat welding flange? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Shaft sleeve forging parts, introduction to forging function advantages and characteristics

2025-5-26 -

What is a National standard carbon steel free forging? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

Introduction to Free forging of oil cylinder and forging structure principle

2025-5-26 -

Introduction to 40CrNiMoA free forging, forging advantages, characteristics and principles

2025-5-26