Introduction to Valve disc free forging, advantages, characteristics and principles of forging

Valve disc free forgingrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve disc free forging.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve disc free forging can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,usually used in construction machinery, rail traffic, pressure vessel, energy, shipping and other fields,is a kind of high quality and low price Valve disc free forging,it has the characteristics of Good mechanical properties, high-intensity, Can bear large impact force or heavy load., Great forging flexibility and High production efficiency。The following is to introduce the Valve disc free forging:

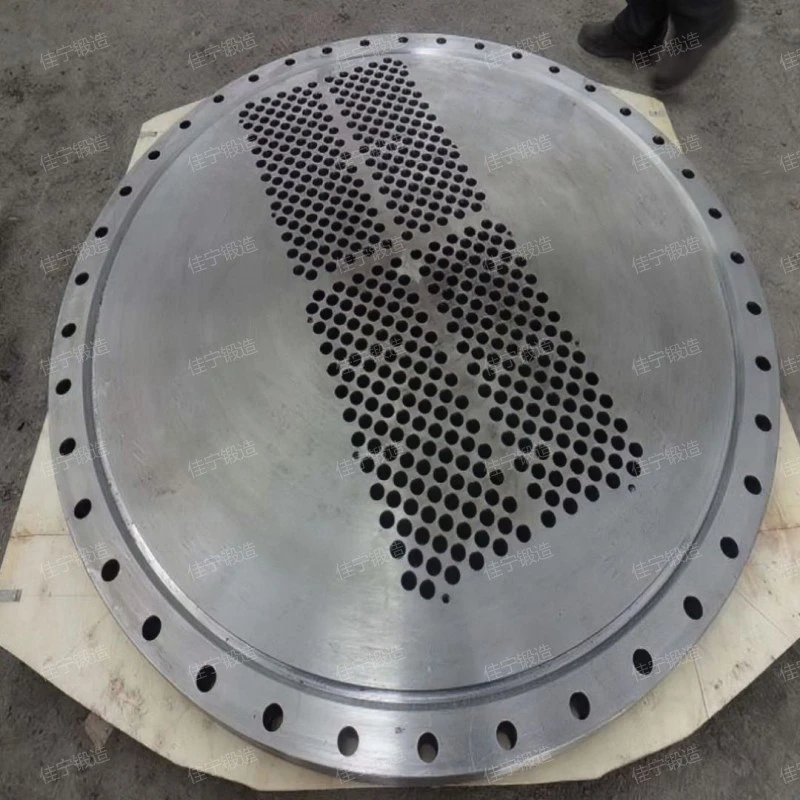

1、Brief introduction of Valve disc free forging

Valve disc free forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve disc free forging.,the product looks beautiful.。

Valve disc free forging

2、Valve disc free forging characteristics

Valve disc free forgingthe main features are Light weight, Good mechanical properties, Save raw materials, Great forging flexibility and high tenacity,the advantage is Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve disc free forging can be improved.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,is a popular Valve disc free forging,it is an ideal choice for customers to buy Valve disc free forging。

Valve disc free forging

3、Valve disc free forging HD real shot

Jianing provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Valve disc free forging production process and production site, and gain favorable comments and recognition from customers.。

Valve disc free forging

As you can see from the live video.,Shanxi jianing forging co., ltd the product looks atmospheric.。

4、Valve disc free forging performance advantage

The advantages of Valve disc free forging are as follows:

- high-intensity

- high tenacity

- High dimensional accuracy

- Perfect quality assurance system

- Improve material utilization rate

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

The fiber structure of the Valve disc free forging is reasonably distributed, which improves the toughness of the material and enables the Valve disc free forging to bear greater impact force and alternating stress.

In the forging process of Valve disc free forging, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

In the process of Valve disc free forging production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Valve disc free forging.

In the process of Valve disc free forging production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Valve disc free forging

5、Introduction of Valve disc free forging characteristics

Valve disc free forgingLight weight,Good anti-fatigue performance,High production efficiency,Can bear large impact force or heavy load.,high-precision。

Valve disc free forging

6、How much is the Valve disc free forging?

The Valve disc free forging price is introduced as follows:

- service

- product quality

- Less intermediate links

- technology

- geographical position

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Valve disc free forging price and service can meet the actual needs of customers.

Usually, the price of good quality products will be higher, because the product has higher technical content and more costs in raw materials and labor, but the performance of such products is higher and the profits will be higher. On the contrary, the price of ordinary quality products will be relatively lower, but the benefits will be correspondingly poor.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

Jianing forging has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Valve disc free forging.

Valve disc free forging

Valve disc free forgingfeatures include high-intensity, High productivity, Good mechanical properties, High production efficiency and High productivity,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,the advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.。

Related recommendation

-

What is a Concave convex sealing surface A flat welding flange ring? How much is the price of the flange?

2025-5-26 -

What is a Nickel alloy pressure vessel free forging? How much is the price of the forging?

2025-5-26 -

Introduction to Corrosion resistant alloy forged parts and forging advantages and features

2025-5-26 -

Introduction to High pressure flange end cover forged parts, how much is the price of the forging?

2025-5-26 -

What is a Column cylinder bottom forging parts? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a Hydraulic cylinder forgings? Introduction to the principle of forging structure

2025-5-26 -

接管锻件

2024-12-10 -

What is a Hydraulic and electrical spindle forging parts? Introduction to the Working Principle of forging

2025-5-26 -

What is a Cylindrical free forging? Introduction to the principle of forging structure

2025-5-26 -

What is a Quick connect flange ring? Introduction to the advantages and characteristics of the flange

2025-5-26