Introduction to Disc-shaped forged parts, forging advantages, characteristics and principles

Disc-shaped forged partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,the product looks beautiful.。

1、Brief introduction of Disc-shaped forged parts

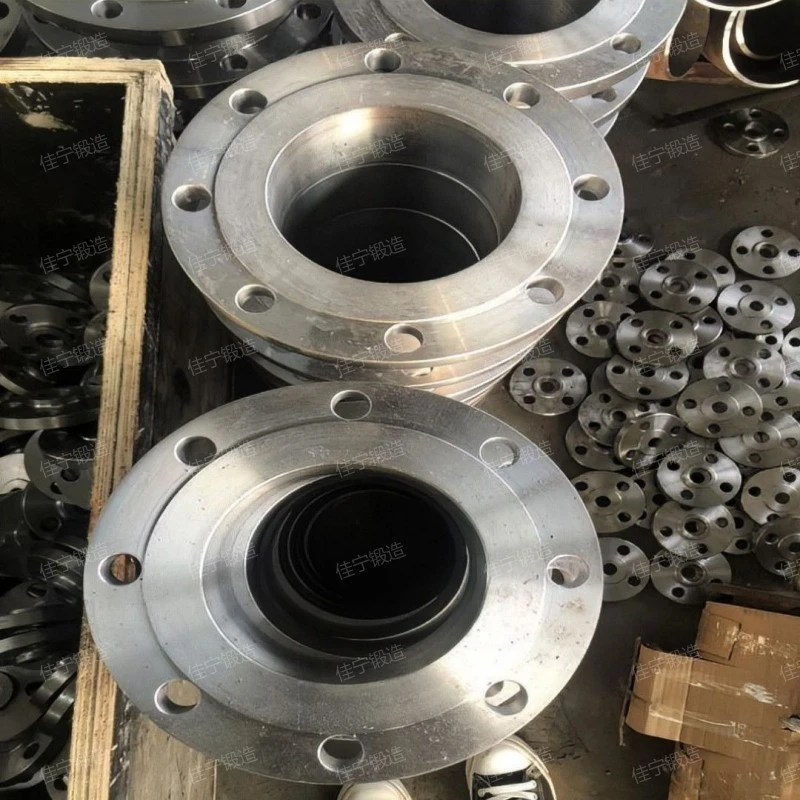

Disc-shaped forged partsrefers to the workpiece or blank obtained by forging metal blank.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Disc-shaped forged parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,is a Disc-shaped forged parts。

Disc-shaped forged parts

2、Introduction of Disc-shaped forged parts characteristics

Disc-shaped forged partsthe main features are High productivity, Good mechanical properties, High productivity, Save raw materials and Great forging flexibility,the advantage is By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Disc-shaped forged parts can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,widely used in construction machinery, rail traffic, power, automobile, war industry and other fields。

Disc-shaped forged parts

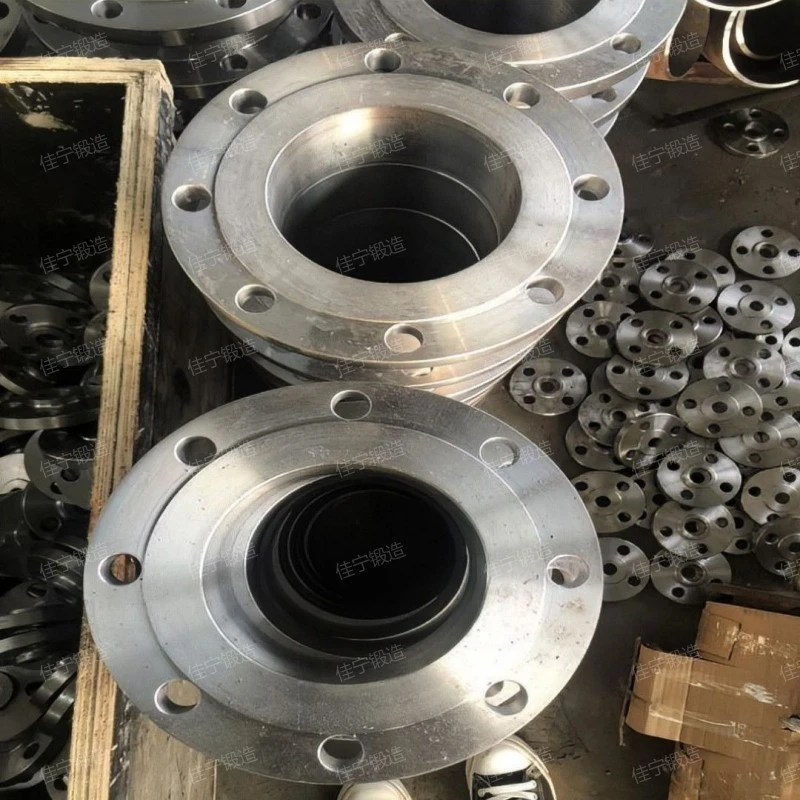

3、Disc-shaped forged parts real shot picture

High-definition map of Disc-shaped forged parts is displayed, and the high-definition map of factory area is taken by Jianing forging for reference of our customers.。

Disc-shaped forged parts

Note: All the pictures in this article were taken by Jianing manufacturer.。

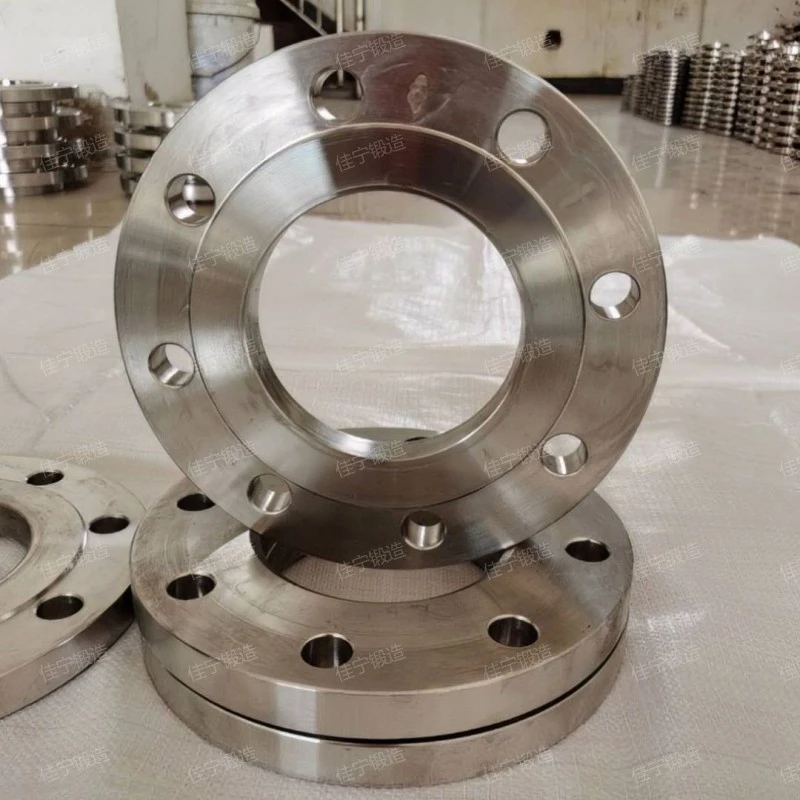

4、Disc-shaped forged parts real beat

A high-definition picture list of Disc-shaped forged parts is available for our customers to visit. The physical visit can be made to the factory. The address of the visit is Xinzhou, and the time can be reserved in advance. The manufacturer has a special person to receive it.。

Disc-shaped forged parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、How much is the Disc-shaped forged parts?

The Disc-shaped forged parts price is introduced as follows:

- raw material

- Company size

- market supply and demand

- Reasonable cost

- Model size

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Direct selling by manufacturers and sales by middlemen will also affect product prices. There are not too many links among direct selling products, so the cost required by manufacturers is low, and the price of Disc-shaped forged parts is low. Customers can also put products into production in advance. On the contrary, when purchasing products from middlemen, there are not only many links, but also the price of Disc-shaped forged parts is much higher, so customers should choose products directly sold by manufacturers when purchasing.

Market change is the main factor that affects the price level. Because of the instability and uncertainty of the market, the sales price of Disc-shaped forged parts will fluctuate greatly, and the market changes are various.

Cost plays a decisive role in the price. The cost mainly includes the initial investment of the product, such as time, manpower and materials selected. The more the investment cost, the higher the relative product pricing. On the contrary, the less the input cost, the lower the price.

Specifications and models have a great influence on the price of Disc-shaped forged parts, so different specifications and models have different selling prices. Customers can reasonably select product specifications and models according to their own needs, so that products can meet their own required standards in terms of specifications and prices.

Disc-shaped forged parts

6、Jianing service

Service has a starting point, and satisfaction has no end. Jianing forging provides services such as free design scheme before sale, free installation and debugging of products during sale, and regular return visits after sale to solve customer problems in time. If you have special requirements for products, manufacturers also support tailor-made.。

Jianing

Disc-shaped forged partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,is a kind of high quality and low price Disc-shaped forged parts。

Related recommendation

-

What is a Forged parts of valve box? How much is the price of the forging?

2025-5-26 -

What is a Austenitic stainless steel flange? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Flat welded flange for heat exchanger connection, introduction to flange advantages and characteristics

2025-5-26 -

What is a Square flat welding flange ring? Introduction to the principle of flange structure

2025-5-26 -

What is a 45Mn2 forging? Introduction to the principle of forging structure

2025-5-26 -

What is a 20 inch flange ring? flange specifications, models, and parameters

2025-5-26 -

Introduction to Conical spindle forging, how much is the price of the forging?

2025-5-26 -

What is a 35CrMnSi forged parts? forging specifications, models, and parameters

2025-5-26 -

Introduction to Plate type flat welded carbon steel flange cover, how much is the price of the flange?

2025-5-26 -

What is a Quick connect blind flange? Introduction to the Working Principle of blind plate

2025-5-26