Introduction to Conical bearing forgings and forging working principle

Conical bearing forgingsrefers to the workpiece or blank obtained by forging metal blank.。

1、Brief introduction of Conical bearing forgings

Conical bearing forgingsrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks beautiful.,it has been widely used in metallurgy, construction machinery, pressure vessel, automobile, shipping and other industries,it has the characteristics of Great forging flexibility, Can bear large impact force or heavy load., Good anti-fatigue performance, Light weight and high-intensity,is developed and improved by Jianing。

Conical bearing forgings

2、Conical bearing forgings introduction video

The following is the live video of Conical bearing forgings designed and produced by Jianing forging for users, from which we can see the Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting. of Conical bearing forgings.。

Conical bearing forgings

As you can see from the live video.,Shanxi jianing forging co., ltd plastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

3、Conical bearing forgings characteristics

Conical bearing forgingsthe main features are high-precision, high tenacity, Save raw materials, Good anti-fatigue performance and Great forging flexibility,it is an ideal choice for customers to buy Conical bearing forgings。

Conical bearing forgings

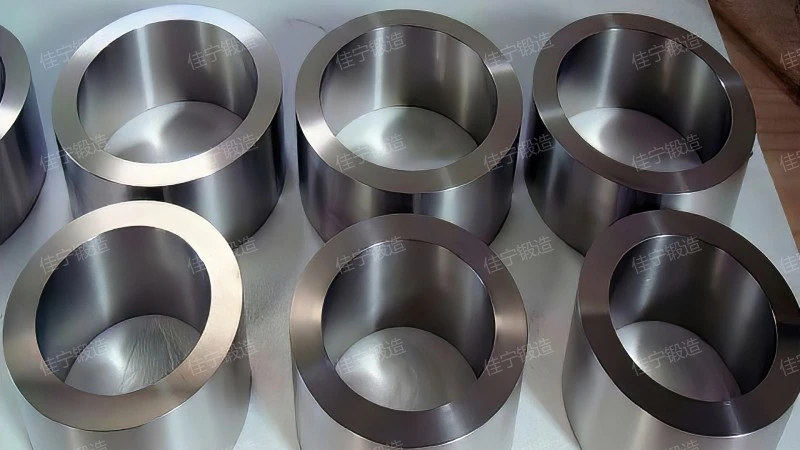

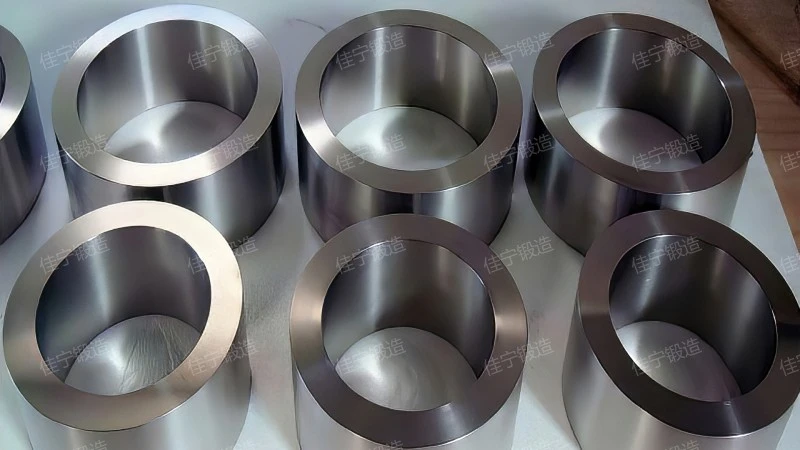

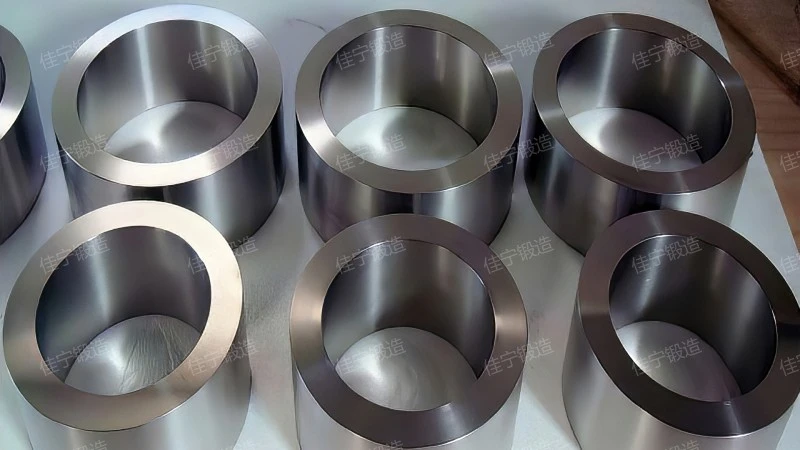

4、On-site real shot of Conical bearing forgings

High-definition pictures of reliable Conical bearing forgings at a glance。

Conical bearing forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、Conical bearing forgings price concessions

The Conical bearing forgings price is introduced as follows:

- Reasonable cost

- raw material

- service

- regional difference

- Sales model

A Conical bearing forgings needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Conical bearing forgings price and service can meet the actual needs of customers.

If the location of the manufacturer is superior, its transportation will be more convenient. Jianing forging address:Xinzhou has convenient transportation, which provides a good convenience for the transportation of Conical bearing forgings.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Conical bearing forgings is low.

Conical bearing forgings

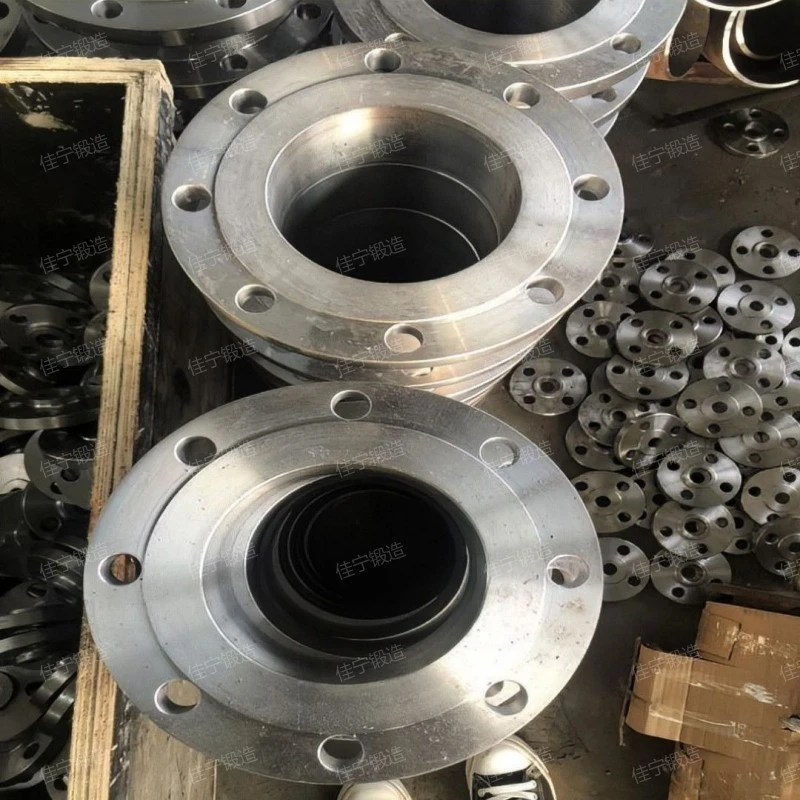

6、Jianing forging workshop pictures

The finished products of the Conical bearing forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Conical bearing forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Conical bearing forgingsfeatures include High productivity, Good mechanical properties, High production efficiency, high-precision and Can bear large impact force or heavy load.,the advantage is After forging, its structure and mechanical properties can be improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Conical bearing forgings can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

Related recommendation

-

Introduction to DN2800 flange cover, how much is the price of the flange?

2025-5-26 -

Introduction to 45 # steel forging, advantages, characteristics and principles of forging

2025-5-26 -

What is a 20MnMo forged parts? Introduction to the Working Principle of forging

2025-5-26 -

Introduction to Half axis forged parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Q345d flat welded flange cover, flange specifications, model parameters

2025-5-26 -

What is a 316L concave face welded flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Bearing outer ring forging? forging specifications, models, and parameters

2025-5-26 -

Introduction to SAE gear ring, introduction to ring gear function advantages and characteristics

2025-5-26 -

Introduction to Low carbon steel flange cover and flange working principle

2025-5-26 -

What is a Convex flat plate flat welding flange? How much is the price of the flange?

2025-5-26