Introduction to Forging parts of rotary bearing ring, introduction to forging function advantages and characteristics

Forging parts of rotary bearing ringrefers to the workpiece or blank obtained by forging metal blank.,High productivity,high-intensity,high-precision,Can bear large impact force or heavy load.,Save raw materials,the advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forging parts of rotary bearing ring can be improved.。

1、Brief introduction of Forging parts of rotary bearing ring

Forging parts of rotary bearing ringis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.。

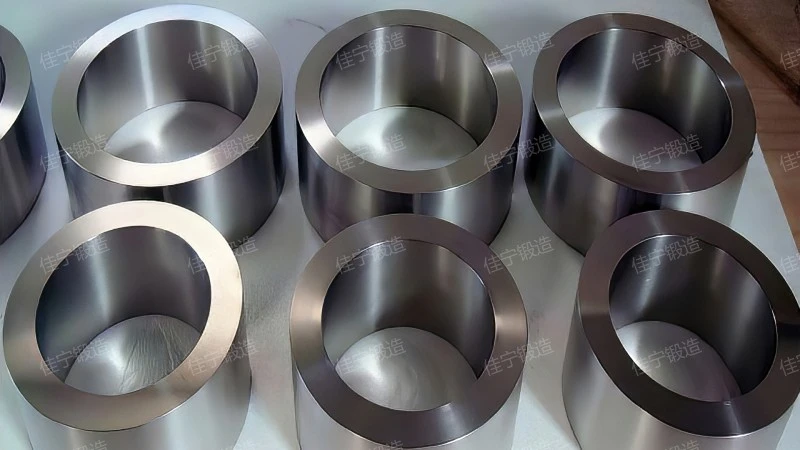

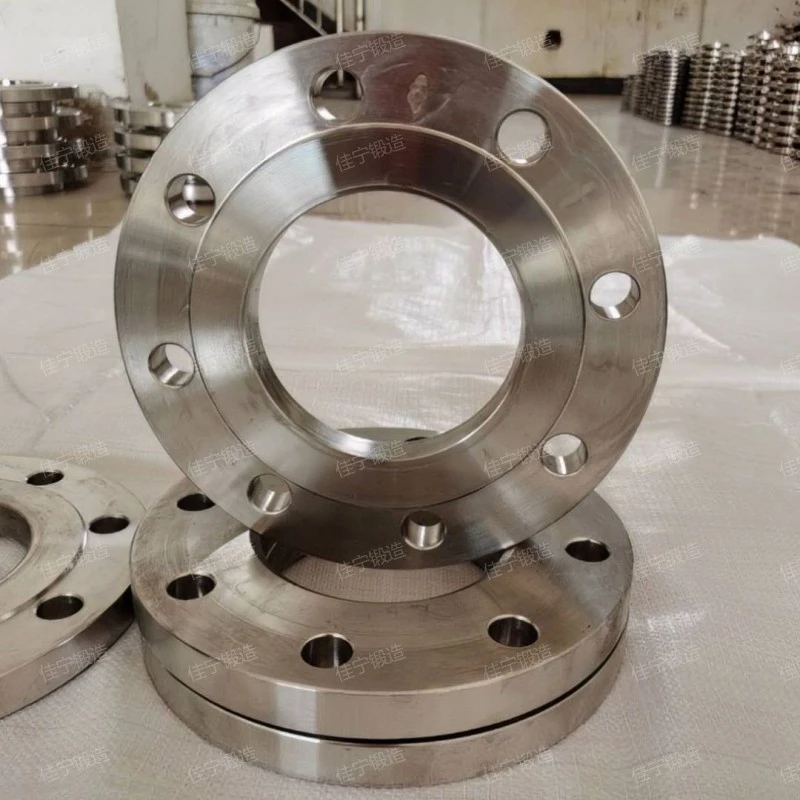

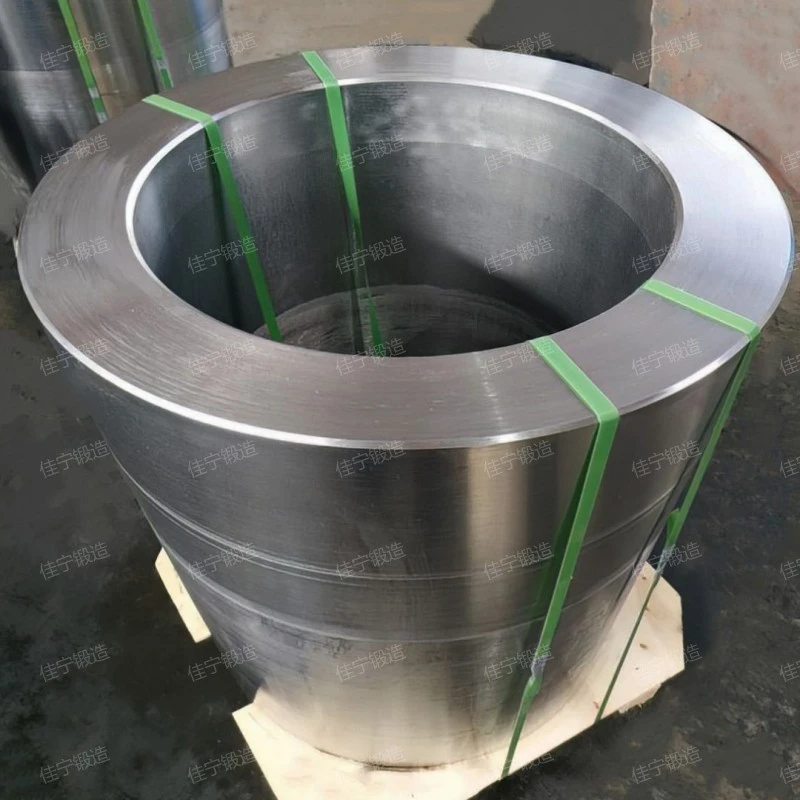

Forging parts of rotary bearing ring

2、Forging parts of rotary bearing ring performance advantage

Forging parts of rotary bearing rings have the following advantages.

- Good fatigue resistance.

- Improve material utilization rate

- Good chemical uniformity

- Optimizing structural design

- high-intensity

The particle flow inside the Forging parts of rotary bearing ring flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In the process of Forging parts of rotary bearing ring production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Forging parts of rotary bearing ring have excellent chemical uniformity.

On the premise of ensuring the design strength, through reasonable structural design, the Forging parts of rotary bearing ring can be lighter than the casting, thus reducing the overall weight of the machine or equipment and reducing energy consumption and cost.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

Forging parts of rotary bearing ring

3、Introduction of Forging parts of rotary bearing ring characteristics

Forging parts of rotary bearing ringfeatures include high tenacity, Great forging flexibility, High production efficiency, Light weight and High productivity,usually used in rail traffic, automobile, manufacturing industry, war industry, pressure vessel and other fields,has been favored by more and more customers.。

Forging parts of rotary bearing ring

4、Forging parts of rotary bearing ring customer scene picture

The Forging parts of rotary bearing ring has a beautiful appearance and atmosphere for our customers' reference.。

Forging parts of rotary bearing ring

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

5、How much is the Forging parts of rotary bearing ring?

The Forging parts of rotary bearing ring price is introduced as follows:

- Sales model

- After-sales service level

- product function

- mass discrepancy

- brand

If there is no middleman to earn the difference, then the Forging parts of rotary bearing ring price will naturally decrease. Jianing forging adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing Forging parts of rotary bearing ring manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Forging parts of rotary bearing ring price can meet the purchasing needs of customers.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Quality is the fundamental factor that determines the price. The better the quality, the more detailed the manufacturing process, the more careful the materials are, the better the performance is, and the price will naturally be more expensive.

Different brands of products in the same series have more or less differences in product prices, and different brands of Forging parts of rotary bearing ring have more or less differences in price.

Forging parts of rotary bearing ring

6、Company service

Jianing has perfect and reasonable after-sales service, which can solve customers' problems in a short time and reduce customers' losses. Jianing forging can provide strong protection for customers in the later stage.。

Jianing

Forging parts of rotary bearing ringthe product looks atmospheric.,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。

Related recommendation

-

Introduction to Flat welding pressure vessel flange cover, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Q255C Carbon Steel Forging Parts, advantages, characteristics and principles of forging

2025-5-26 -

Introduction to Quick welding flange, introduction to flange function advantages and characteristics

2025-5-26 -

What is a Quick opening flange cover? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

Introduction to Circle free forging, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Groove flange ring, flange advantages, characteristics and principles

2025-5-26 -

Introduction to Flat welding convex flange cover with plate type, advantages, characteristics and principles of flange

2025-5-26 -

煤磨收尘风机轴毛坯

2024-12-10 -

Introduction to Roller free forging, introduction to forging function advantages and characteristics

2025-5-26 -

Introduction to Threaded movable flange and flange structure principle

2025-5-26