What is a Forged parts of oil seal gasket ring? How much is the price of the forging?

Forged parts of oil seal gasket ringrefers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,the product looks beautiful.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil seal gasket ring can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,is a popular Forged parts of oil seal gasket ring,has been favored by more and more customers.。The following is to introduce the Forged parts of oil seal gasket ring:

1、Brief introduction of Forged parts of oil seal gasket ring

Forged parts of oil seal gasket ringrefers to the workpiece or blank obtained by forging metal blank.,it is widely used inmetallurgy,automobile,energy,manufacturing industry,rail traffic and other industries,Save raw materials,Good mechanical properties,high-intensity,high-precision,Good anti-fatigue performance。

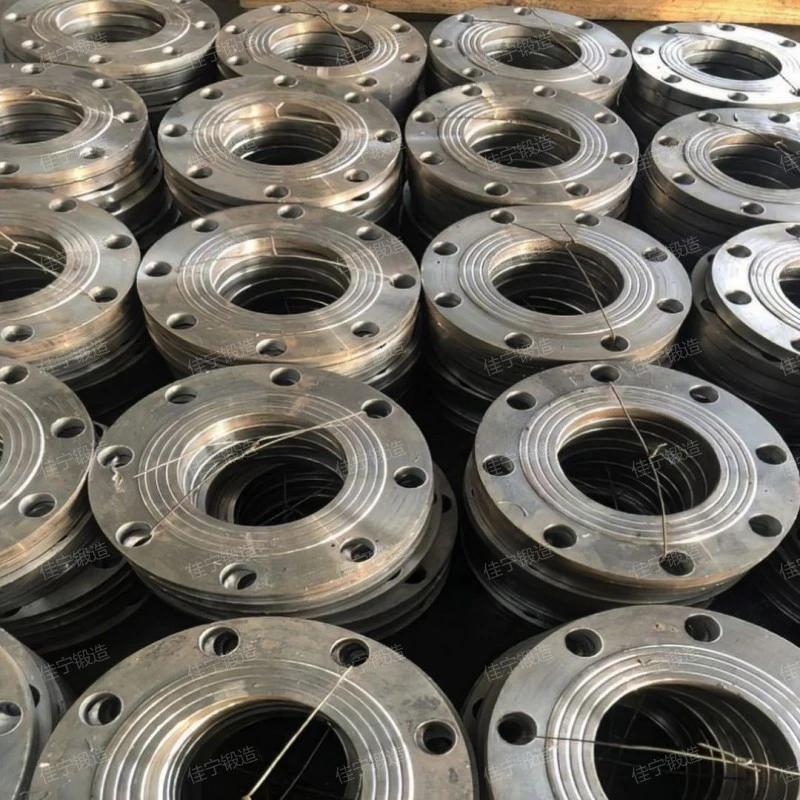

Forged parts of oil seal gasket ring

2、Video analysis of Forged parts of oil seal gasket ring

Speak directly with facts on the spot。

Forged parts of oil seal gasket ring

As you can see from the live video.,Jianing the product looks atmospheric.。

3、Introduction of Forged parts of oil seal gasket ring characteristics

Forged parts of oil seal gasket ringthe main features are High production efficiency, high tenacity, High productivity, Great forging flexibility and high tenacity,the advantage is Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil seal gasket ring can be improved.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,is a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil seal gasket ring.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.。

Forged parts of oil seal gasket ring

4、Forged parts of oil seal gasket ring working site

On-site aerial photography of Forged parts of oil seal gasket ring。

Forged parts of oil seal gasket ring

As you can see from the live video.,Shanxi jianing forging co., ltd the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil seal gasket ring.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil seal gasket ring can be improved.。

5、Forged parts of oil seal gasket ring price advantage

The Forged parts of oil seal gasket ring price is introduced as follows:

- Brand strength

- product function

- brand

- Overall configuration

- Low cost of raw materials

At present, there are various brands of Forged parts of oil seal gasket ring in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Forged parts of oil seal gasket ring are different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Different brands of products in the same series have more or less differences in product prices, and different brands of Forged parts of oil seal gasket ring have more or less differences in price.

Usually, the quotation of Forged parts of oil seal gasket ring changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

A Forged parts of oil seal gasket ring needs to spend a lot of manufacturing costs from research and development to production to sales, including raw material costs, technical costs, labor costs, etc. The higher the manufacturing cost, the higher the price will be.

Forged parts of oil seal gasket ring

6、Jianing forging after-sales service

Our company can provide you with all-round, high-quality and professional services, especially in after-sales service, which has been unanimously recognized and favored by our customers.。

Jianing

Forged parts of oil seal gasket ringfeatures include Good mechanical properties, high-intensity, Light weight, Good anti-fatigue performance and Can bear large impact force or heavy load.,widely used inpower,automobile,energy,rail traffic,manufacturing industry and other industries,the advantage is Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Forged parts of oil seal gasket ring can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Forged parts of oil seal gasket ring.、After forging, its structure and mechanical properties can be improved.。

Related recommendation

-

What is a Blind flange with holes? Introduction to the advantages and characteristics of the blind plate

2025-5-26 -

Introduction to Concave convex flat welding flange cover and flange advantages and features

2025-5-26 -

What is a DN1000 flange cover? Introduction to the advantages, characteristics, and principles of the flange

2025-5-26 -

Introduction to Convex flat welded steel flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Convex surface flat welding method steel flange, flange specifications, model parameters

2025-5-26 -

Introduction to Alloy steel pipe flange and tube sheet working principle

2025-5-26 -

Introduction to PL flat welding flange and flange advantages and features

2025-5-26 -

What is a Forged parts for pressure vessel end caps? How much is the price of the forging?

2025-5-26 -

Introduction to 16Mn flat welding flange plate and flange working principle

2025-5-26 -

轴承套锻件

2024-12-10