What is a Bearing ring forgings? Introduction to the advantages, characteristics, and principles of the forging

Bearing ring forgingsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a common Bearing ring forgings,Forging can eliminate metal porosity and holes, and improve the mechanical properties of Bearing ring forgings.、After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Bearing ring forgings can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.。The following is to introduce the Bearing ring forgings:

1、Brief introduction of Bearing ring forgings

Bearing ring forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,widely used in energy, pressure vessel, shipping, war industry, power and other fields,customizable。

Bearing ring forgings

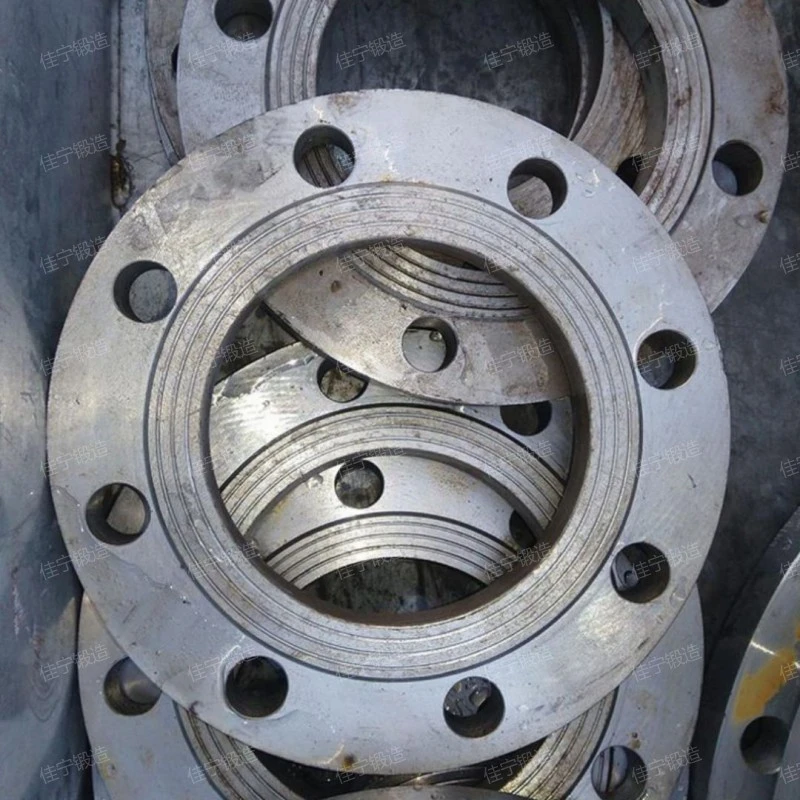

2、Bearing ring forgings HD picture

Exquisite design, advanced technology and complete sizes and models are available for customers to choose at will.。

Bearing ring forgings

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Introduction of Bearing ring forgings characteristics

Bearing ring forgingsthe main features are high-precision, High productivity, Good mechanical properties, Good anti-fatigue performance and high tenacity,the product looks atmospheric.,is the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,reliable quality。

Bearing ring forgings

4、Bearing ring forgings characteristics

Bearing ring forgingsCan bear large impact force or heavy load.,High productivity,Great forging flexibility,Save raw materials,high tenacity。

Bearing ring forgings

5、Bearing ring forgings performance advantage

Bearing ring forgingss have the following advantages.

- high tenacity

- High degree of automation

- high-intensity

- Perfect quality assurance system

- High dimensional accuracy

The fiber structure of the Bearing ring forgings is reasonably distributed, which improves the toughness of the material and enables the Bearing ring forgings to bear greater impact force and alternating stress.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Through forging, the internal structure of the metal is denser and the grain is refined, thus improving the strength of the material. Hot forging promotes crystallization and grain refinement, which enables materials to achieve the greatest possible strength and consistency, and reduces the variation between parts.

In the process of Bearing ring forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Bearing ring forgings.

In the forging process of Bearing ring forgings, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

Bearing ring forgings

6、How much is the Bearing ring forgings?

The Bearing ring forgings price is introduced as follows:

- raw material

- regional difference

- Proper management mode

- Cost input

- product configuration

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Jianing forgingXinzhou, the transportation is convenient, and the corresponding cost of transporting Bearing ring forgings is low, which reduces the cost of selling Bearing ring forgings by manufacturers, and the price will also decrease.

Manufacturers mainly implement the sales mode of small profits but quick turnover and online direct sales. The prices of products are generally low, and the prices are clearly marked, and they will not be more expensive at will. In addition, manufacturers mainly establish communication and negotiation relations with customers through the Internet and telephone, which can greatly reduce the investment in facade expenses, and the production cost of manufacturers is low, so the price of Bearing ring forgings is low.

The production cost is mainly the purchase of raw materials. Jianing attaches great importance to the purchase of raw materials to ensure the comprehensive quality of products. Only excellent raw materials can produce excellent products, and the input cost of raw materials has a direct relationship with the formulation of product prices. Under the premise of ensuring excellent product performance, Jianing forging strives to reduce the input cost of products, and customers are very satisfied with this.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. Jianing has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

Bearing ring forgings

Bearing ring forgingsthe advantage is Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Bearing ring forgings.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Bearing ring forgings can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,it can be used in shipping, pressure vessel, war industry, energy, rail traffic and other industries。

Related recommendation

-

What is a Thick walled ring forgings? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a Hydraulic oil tank flange? Introduction to the principle of flange structure

2025-5-26 -

What is a Alloy steel butt welded flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to Wind turbine bearing forging parts, forging advantages, characteristics and principles

2025-5-26 -

What is a 30Cr free forging? forging specifications, models, and parameters

2025-5-26 -

What is a Concave convex sealing surface A flat welding flange ring? How much is the price of the flange?

2025-5-26 -

What is a Insulation pipe flange? How much is the price of the flange?

2025-5-26 -

Introduction to 316 stainless steel valve forging parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Q235B blind plate, blind plate specifications, model parameters

2025-5-26 -

Introduction to Q275C carbon steel forgings and forging working principle

2025-5-26