Introduction to Sealing ring forging and forging advantages and features

Sealing ring forgingforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Sealing ring forging can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Sealing ring forging.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.,it is an ideal choice for customers to buy Sealing ring forging。The following is to introduce the Sealing ring forging:

1、Brief introduction of Sealing ring forging

Sealing ring forgingis the metal that exerts pressure to shape the required shape or appropriate compression through plastic deformation.,Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Sealing ring forging.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Sealing ring forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.,usually used in pressure vessel, energy, construction machinery, rail traffic, manufacturing industry and other fields,the product looks beautiful.,it has the characteristics of high tenacity, High productivity, Great forging flexibility, Save raw materials and Light weight。

Sealing ring forging

2、Functional advantages of Sealing ring forging

Sealing ring forgings have the following advantages.

- High degree of automation

- Good chemical uniformity

- Good fatigue resistance.

- Replace other processing methods

- Meet the requirements of complex working conditions

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Forging can disperse the segregation of alloy or nonmetal and make the Sealing ring forging have excellent chemical uniformity.

The particle flow inside the Sealing ring forging flows precisely along the contour of the part, and these continuous streamline lines are beneficial to reduce the incidence of fatigue or common faults.

In some cases, Sealing ring forging can replace parts produced by other processing methods (such as casting, welding, etc.), thus simplifying the production process and improving production efficiency.

The Sealing ring forging has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

Sealing ring forging

3、Sealing ring forging characteristics

Sealing ring forgingHigh production efficiency,Good anti-fatigue performance,Can bear large impact force or heavy load.,high-precision,high tenacity,is developed and improved by Jianing。

Sealing ring forging

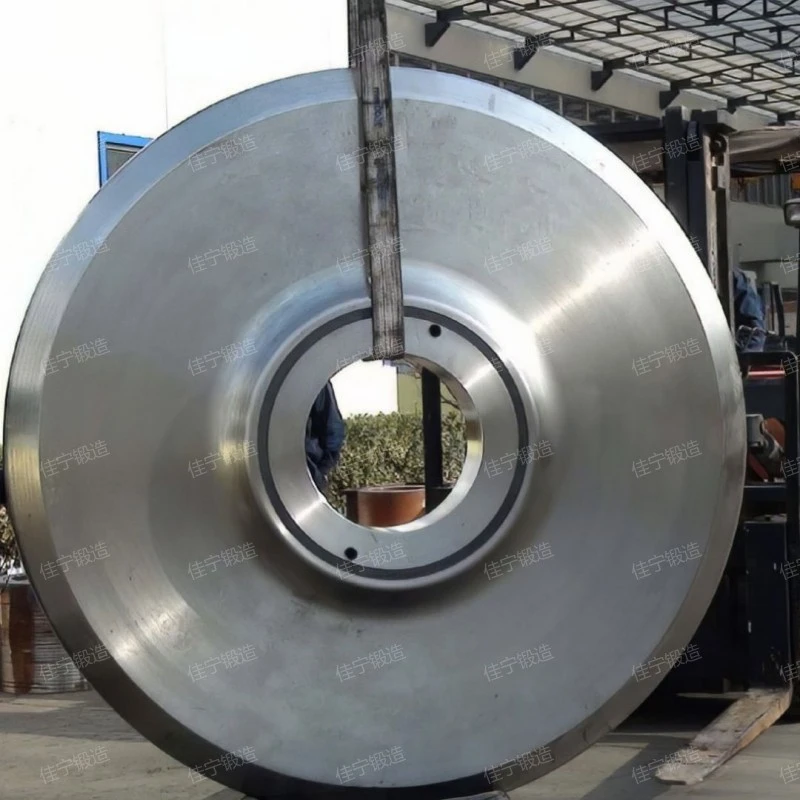

4、Sealing ring forging customer scene picture

Sealing ring forging HD real shot, a variety of specifications and models display, for our customers to choose at will.。

Sealing ring forging

Note: All the pictures in this article were taken by Jianing manufacturer.。

5、How much is the Sealing ring forging?

The Sealing ring forging price is introduced as follows:

- raw material

- service

- After-sales service level

- region

- manufacturing cost

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Sealing ring forging price and service can meet the actual needs of customers.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, Jianing forging Sealing ring forging manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Sealing ring forging price can meet the purchasing needs of customers.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing detailed address:Cuijiazhuang Industrial Park in Dingxiang, Xinzhou City, Shanxi Province, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. Jianing forging has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Sealing ring forging

6、Jianing forging workshop real shot

You can buy Sealing ring forging according to your needs and show you Sealing ring forging videos.。

Sealing ring forging

As you can see from the live video.Jianing features include Good mechanical properties, High production efficiency, high-intensity, Light weight and Great forging flexibility。

Sealing ring forgingthe advantage is After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、After forging, its structure and mechanical properties can be improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.,the product looks atmospheric.,Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Sealing ring forging can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Sealing ring forging.。

Related recommendation

-

Introduction to 15Cr forging and forging structure principle

2025-5-26 -

Introduction to Wind power coupling flange and flange working principle

2025-5-26 -

What is a 6061 aluminum alloy ring forging parts? forging specifications, models, and parameters

2025-5-26 -

What is a Flat welded steel pipe flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to Pipe type flat welded steel pipe flange cover and flange working principle

2025-5-26 -

What is a Ring sealing surface flange? How much is the price of the flange?

2025-5-26 -

Introduction to National standard carbon steel forging parts, how much is the price of the forging?

2025-5-26 -

What is a Forged oil cylinder earrings? Introduction to the advantages, characteristics, and principles of the forging

2025-5-26 -

What is a DN350 flange? Introduction to the advantages and characteristics of flange functions

2025-5-26 -

What is a Hollow free forging? How much is the price of the forging?

2025-5-26