What is a Outer ring forging parts? Introduction to the Working Principle of forging

Outer ring forging partsforging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.,is a kind of Outer ring forging parts manufactured by Jianing。

1、Brief introduction of Outer ring forging parts

Outer ring forging partsthe forging machine is used to exert pressure on the blank.。

Outer ring forging parts

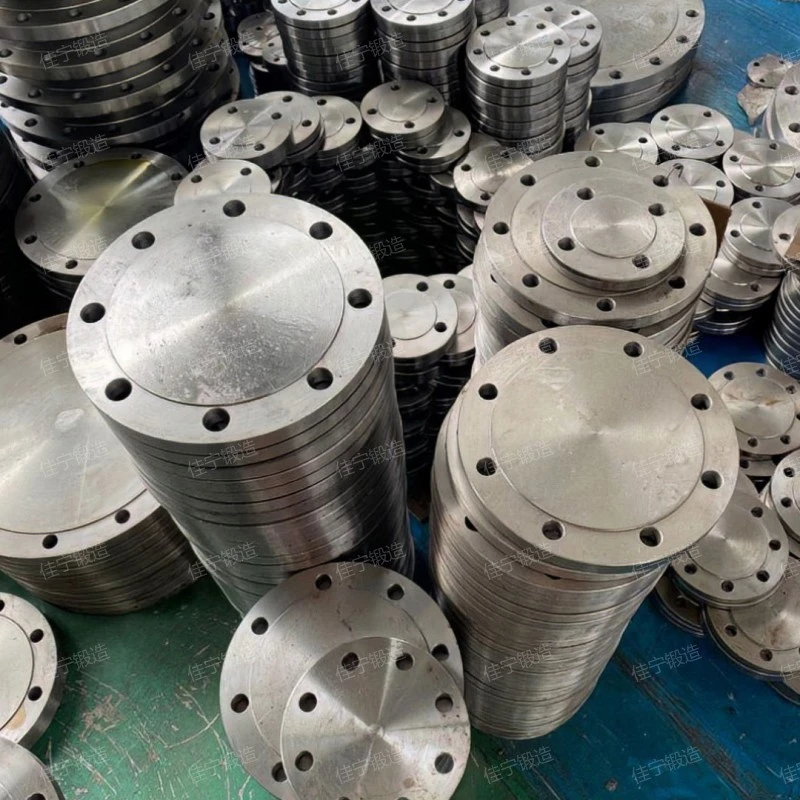

2、Outer ring forging parts customer scene picture

High-definition pictures for various Outer ring forging parts, panoramic display,the product looks beautiful., reliable in quality and trustworthy.。

Outer ring forging parts

Note: All the pictures in this article were taken by Jianing forging manufacturer.。

3、Outer ring forging parts characteristics

Outer ring forging partsit has the characteristics of Good mechanical properties, Good anti-fatigue performance, high-intensity, high tenacity and high-precision,refers to the workpiece or blank obtained by forging metal blank. In the process of forging, the metal blank is plastically deformed under the pressure of forging hammer, press and other equipment, and then its shape, size and organizational structure are changed to meet specific use requirements.,is a common Outer ring forging parts,Cheap and high quality。

Outer ring forging parts

4、Introduction of Outer ring forging parts characteristics

Outer ring forging partsGood mechanical properties,Can bear large impact force or heavy load.,Great forging flexibility,Good anti-fatigue performance,high-intensity,it is an ideal choice for customers to buy Outer ring forging parts。

Outer ring forging parts

5、Outer ring forging parts performance advantage

Outer ring forging partss have the following advantages.

- Eliminate internal defects

- Improve material utilization rate

- High degree of automation

- Perfect quality assurance system

- high tenacity

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Outer ring forging parts.

In the process of Outer ring forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

In the process of Outer ring forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Outer ring forging parts.

The fiber structure of the Outer ring forging parts is reasonably distributed, which improves the toughness of the material and enables the Outer ring forging parts to bear greater impact force and alternating stress.

Outer ring forging parts

6、How much is the Outer ring forging parts?

The Outer ring forging parts price is introduced as follows:

- specifications and models

- technology

- manufacturing cost

- market competition

- product function

Different product models will also affect the price changes. Different specifications and models will lead to different product prices.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Product manufacturers are different, and the cost spent by each manufacturer in producing products is definitely different. The higher the cost of producing products, the higher the price of products set by manufacturers. On the contrary, the Outer ring forging parts price is low.

Market change is one of the factors that affect the price range greatly. Market change is unstable, but there are certain rules to follow. Market change is caused by other factors, such as economic instability, competition among manufacturers and too big difference between supply and demand. These factors are the core reasons that cause the market to fluctuate greatly, and then it will have a bad impact on prices.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Outer ring forging parts

Outer ring forging partsthe advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Outer ring forging parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、After forging, its structure and mechanical properties can be improved.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Outer ring forging parts.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,the product looks atmospheric.。

Related recommendation

-

Introduction to Thick walled flat welded flange, flange specifications, model parameters

2025-5-26 -

Introduction to carbon steel tube sheet, tube sheet advantages, characteristics and principles

2025-5-26 -

Introduction to 40CrNiMoA free forging, forging advantages, characteristics and principles

2025-5-26 -

What is a Card sleeve blind plate? blind plate specifications, models, and parameters

2025-5-26 -

Introduction to Hydraulic cylinder free forging, introduction to forging function advantages and characteristics

2025-5-26 -

磁性环锻件

2024-12-10 -

Introduction to Split ring flange ring, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Q345R alloy forgings and forging working principle

2025-5-26 -

What is a Threaded plate flange? flange specifications, models, and parameters

2025-5-26 -

Introduction to Flat welded pipe flange and flange structure principle

2025-5-26