What is a Valve cover forging parts? Introduction to the Working Principle of forging

Valve cover forging partsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the main features are High productivity, Save raw materials, Good anti-fatigue performance, high-precision and high tenacity,the product looks atmospheric.,can be customized according to user's needs.。

1、Brief introduction of Valve cover forging parts

Valve cover forging partsis a part or blank in which a metal blank is plastically deformed under pressure to obtain the required shape, size and performance.,The price is low and affordable。

Valve cover forging parts

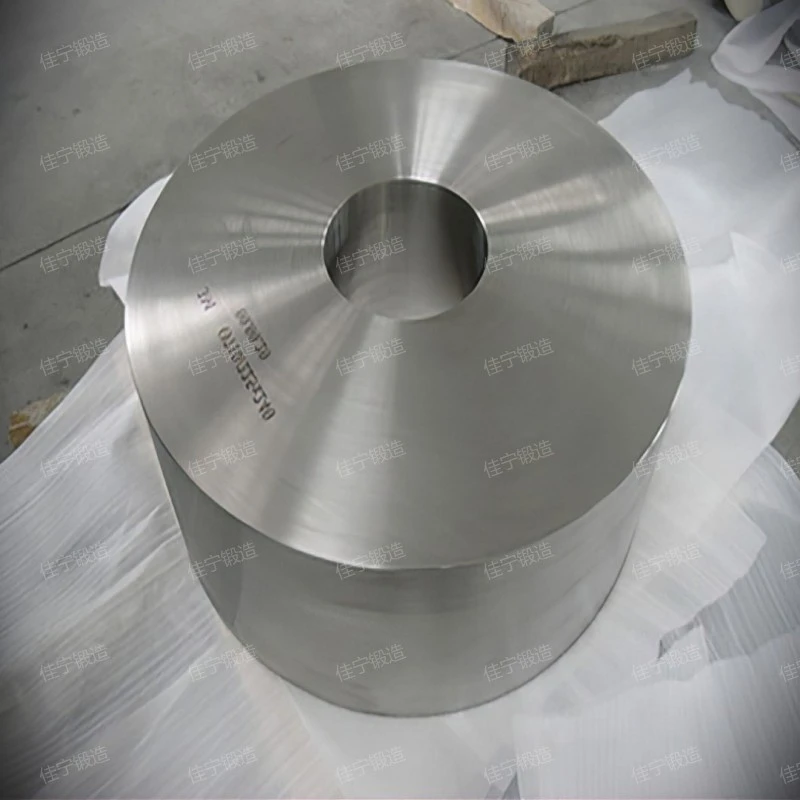

2、Valve cover forging parts HD real shot

Speak directly with facts on the spot。

Valve cover forging parts

As you can see from the live video.,Shanxi jianing forging co., ltd it has the characteristics of Save raw materials, High productivity, High production efficiency, Great forging flexibility and high-precision。

3、Functional advantages of Valve cover forging parts

Valve cover forging partss have the following advantages.

- Improve material utilization rate

- Good chemical uniformity

- Meet the requirements of complex working conditions

- High dimensional accuracy

- Perfect quality assurance system

In the process of Valve cover forging parts production, through accurate blanking and forging process, the utilization rate of raw materials can be maximized and waste can be reduced.

Forging can disperse the segregation of alloy or nonmetal and make the Valve cover forging parts have excellent chemical uniformity.

The Valve cover forging parts has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

In the forging process of Valve cover forging parts, high dimensional accuracy and shape accuracy can be obtained through the precise forming of dies.

In the process of Valve cover forging parts production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Valve cover forging parts.

Valve cover forging parts

4、Valve cover forging parts introduction video

On-site aerial photography of Valve cover forging parts。

Valve cover forging parts

As you can see from the live video.,Jianing forging the advantage is After forging, its structure and mechanical properties can be improved.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve cover forging parts can be improved.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、After forging, its structure and mechanical properties can be improved.。

5、Valve cover forging parts price advantage

The Valve cover forging parts price is introduced as follows:

- market competition

- regional advantages

- Parameter size

- select a qualified person

- select a qualified person

When the market demand for Valve cover forging parts is relatively high, manufacturers will raise the price in order to get more profits. On the contrary, when the market demand for this product is low, manufacturers will lower the price in order to sell the remaining products as soon as possible.

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. Jianing located in Xinzhou., where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

The same product, different specifications and models, the performance of the product is different, therefore, manufacturers need different costs in producing and manufacturing products, so the prices of different specifications and models are different, and customers should give priority to suitability when purchasing.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

The higher the cost of materials, the higher the price will be. In the process of purchasing, customers need to make a detailed understanding of the materials selected for manufacturing products.

Valve cover forging parts

6、Jianing forging delivery site

The following is the live video of Valve cover forging parts designed and produced by Jianing for users, from which we can see the Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、Forging can eliminate metal porosity and holes, and improve the mechanical properties of Valve cover forging parts.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Valve cover forging parts can be improved. of JianingValve cover forging parts.。

Valve cover forging parts

As you can see from the live video.Jianing forging it can be used in automobile, energy, war industry, construction machinery, power and other industries。

Valve cover forging partsfeatures include Light weight, high-intensity, Can bear large impact force or heavy load., Good anti-fatigue performance and Good mechanical properties,is a common Valve cover forging parts。

Related recommendation

-

Introduction to Cr12MoV forged parts, forging advantages, characteristics and principles

2025-5-26 -

Introduction to Strengthen the ring forging parts and forging working principle

2025-5-26 -

What is a Reactor pressure vessel forgings? Introduction to the advantages and characteristics of forging functions

2025-5-26 -

What is a DN15 flange plate? Introduction to the principle of flange structure

2025-5-26 -

煤磨收尘风机轴毛坯

2024-12-10 -

What is a Forged steel flat welding flange? Introduction to the principle of flange structure

2025-5-26 -

Introduction to Steam plate flat welding flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Double sided butt welded flange, introduction to flange advantages and characteristics

2025-5-26 -

Introduction to Q235B flat welded flange cover, introduction to flange function advantages and characteristics

2025-5-26 -

尾轴锻件

2024-12-10