What is a Gate valve forgings? Introduction to the advantages and characteristics of forging functions

Gate valve forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.。

1、Brief introduction of Gate valve forgings

Gate valve forgingsplastic deformation is made to obtain forgings with certain shapes and mechanical properties.,the product looks beautiful.,the advantage is Forging can eliminate metal porosity and holes, and improve the mechanical properties of Gate valve forgings.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Gate valve forgings can be improved.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、After forging and hot working. Due to the deformation and recrystallization of metal, the structure is more compact, and the plasticity and mechanical properties of metal are improved.、Forging can be used to exert pressure on the blank, so that it can produce plastic deformation and change its mechanical properties.,support customization。

Gate valve forgings

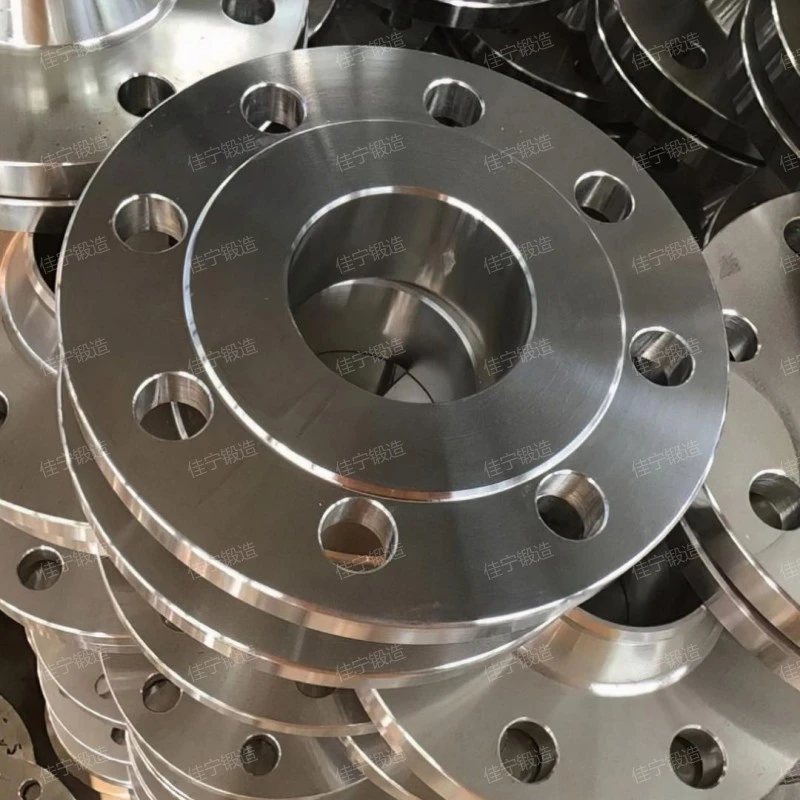

2、Gate valve forgings HD real shot

Gate valve forgings styles and designs are diverse, specifications and models can be customized according to customer needs, providing high-definition pictures for new and old customers' reference.。

Gate valve forgings

Note: All the pictures in this article were taken by Jianing manufacturer.。

3、Video analysis of Gate valve forgings

Speak directly with facts on the spot。

Gate valve forgings

As you can see from the live video.,Shanxi jianing forging co., ltd the advantage is After forging, its structure and mechanical properties can be improved.、Forging machinery can be used to exert pressure on the blank to make it deform plastically, so as to obtain certain mechanical properties.、Forging can eliminate the defects of as-cast porosity and optimize the microstructure of metals during smelting.、Forging can not only obtain the shape of mechanical parts, but also improve the internal structure of metal and improve the mechanical and physical properties of metal.、By forging, not only mechanical parts can be obtained, but also the internal structure of metal can be improved, and the mechanical and physical properties of Gate valve forgings can be improved.。

4、Functional advantages of Gate valve forgings

Gate valve forgingss have the following advantages.

- Eliminate internal defects

- Perfect quality assurance system

- Meet the requirements of complex working conditions

- Reduce the amount of subsequent processing

- High degree of automation

During the forging process, the porosity, shrinkage cavity, cracks and other defects in the metal are closed under the action of high temperature and pressure, thus improving the structural integrity of the Gate valve forgings.

In the process of Gate valve forgings production, a perfect quality assurance system is established, and the raw materials, production process and finished product inspection are strictly controlled to ensure the reliable quality of the Gate valve forgings.

The Gate valve forgings has excellent mechanical properties and structural integrity, which can meet the use requirements under complex working conditions and ensure the long-term stable operation of the equipment.

The forming precision of the Gate valve forgings is high, and the subsequent processing amount is relatively small, thus saving the processing cost and time.

Modern forging equipment has a high degree of automation, which can realize continuous and efficient production and greatly improve production efficiency.

Gate valve forgings

5、How much is the Gate valve forgings?

The Gate valve forgings price is introduced as follows:

- cost of production

- Different regions

- Configuration difference

- Manufacturer's strength

- Brand strength

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. Jianing forging has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Jianing has a geographical advantage, where the transportation is developed, the product transportation cost is low, and the price and consumption level are also low, which provides a good sales environment for Gate valve forgings.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. Jianing forging pays special attention to the hardware configuration of products, so Jianing Gate valve forgings has a higher cost performance.

There are many manufacturers of products in Shanxi, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Gate valve forgings is naturally different.

At present, there are various brands of Gate valve forgings in Shanxi Xinzhou. The performance, quality and after-sales of products under different brands are different, and the prices of Gate valve forgings are different.

Gate valve forgings

6、Jianing forging workshop picture real shot

The finished products of the Gate valve forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Jianing

The finished products of the Gate valve forgings factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Gate valve forgingsit is widely used inautomobile,energy,shipping,war industry,metallurgy and other industries,forging equipment is used to apply external force to the blank, so that the metal blank is plastically deformed, so as to obtain forgings with required geometric shape and quality.。

Related recommendation

-

What is a Electric shaft forgings? Introduction to the principle of forging structure

2025-5-26 -

What is a Steam pressure kettle flange cover? flange specifications, models, and parameters

2025-5-26 -

Introduction to 42CrMo4 forging, advantages, characteristics and principles of forging

2025-5-26 -

火车轮辋锻件

2024-12-10 -

回转支承环锻件

2024-12-10 -

Introduction to Groove flat welding flange cover, flange specifications, model parameters

2025-5-26 -

Introduction to Threaded two hole flange ring, how much is the price of the flange?

2025-5-26 -

Introduction to Threaded welded flange and flange structure principle

2025-5-26 -

吊钩锻件

2024-12-10 -

Introduction to Short tube threaded flange and flange advantages and features

2025-5-26